General purpose grade emphasizing wear resistance | Carbide grade for Swiss CNC lathes

General purpose grade emphasizing wear resistance | Carbide grade for Swiss CNC lathes

A best seller for Swiss CNC lathes

General purpose grade machining various workpiece materials

Balance of toughness, wear resistance and sharp cutting edge

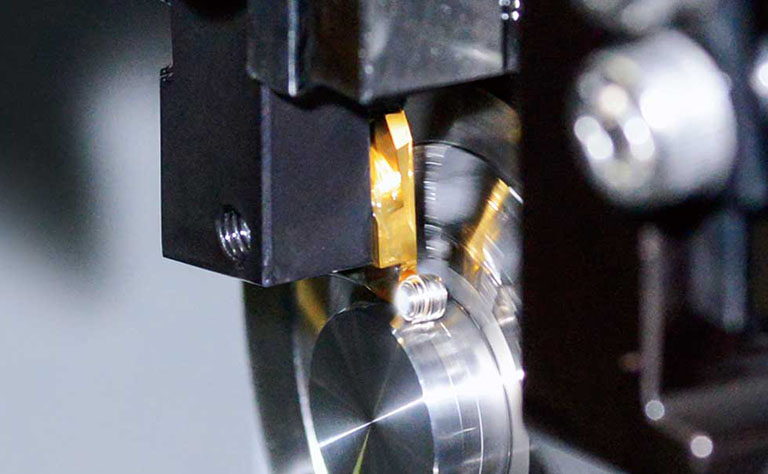

Features

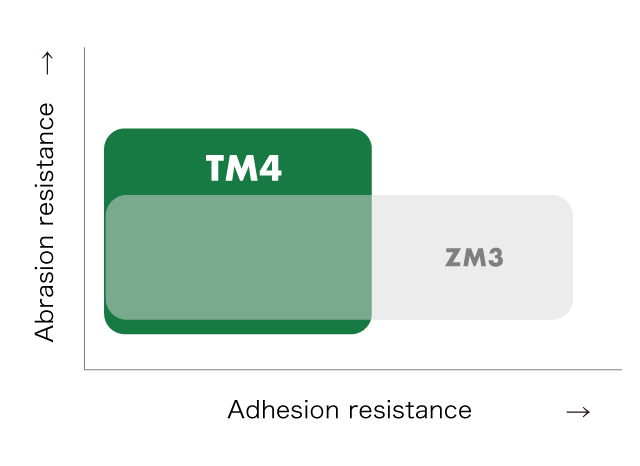

- General purpose grade with a thin TiN-TiCN-TiN coat that is exceptionally smooth to improve adhesion resistance and sharpness

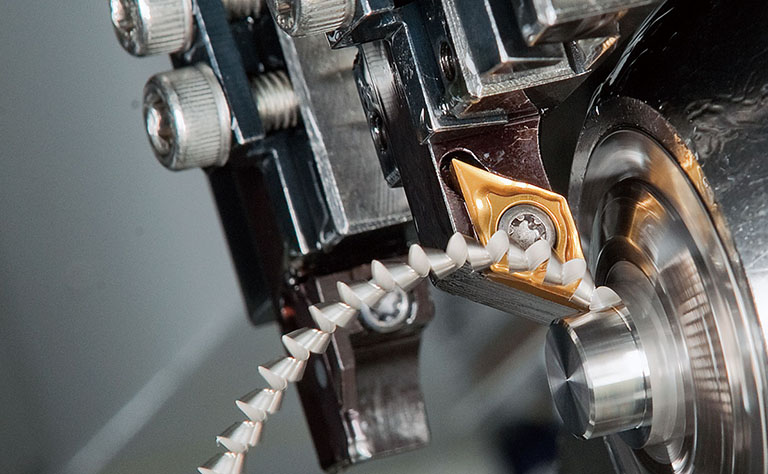

Tooling application

Successfully machines various workpiece materials.

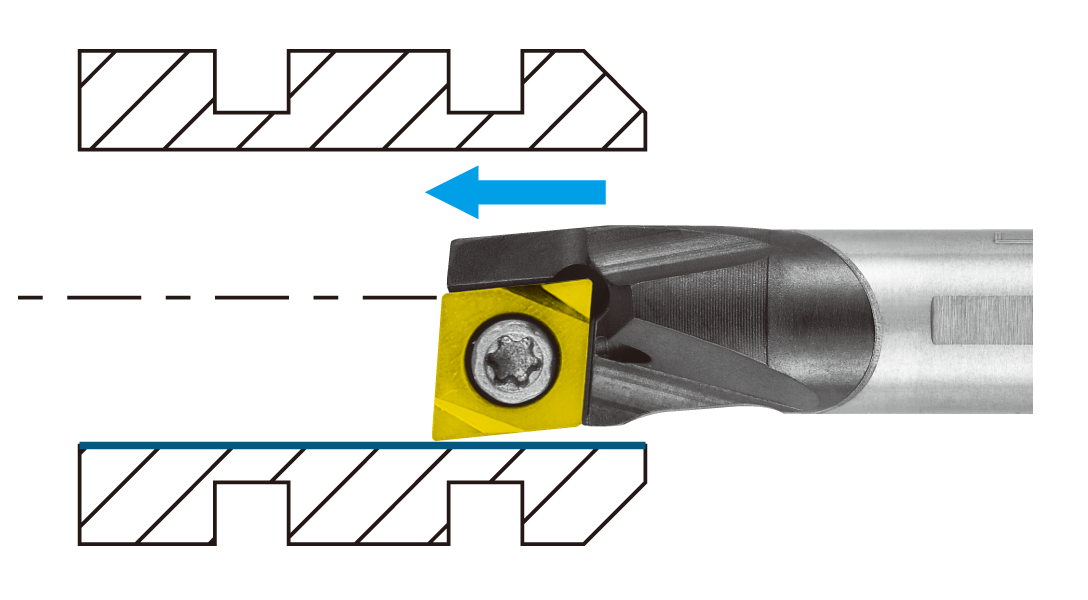

Front turning / Back turning / Grooving / Cut off / ID boring / Socket machining / Milling

TM4 comparison chart

Case study

| Auto parts | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| TM4 | 950 pcs / corner |

| Competitor’s PVD coated carbide | 500 pcs / corner |

TM4 achieved 1.9 times longer tool life compared to the competitor's insert with stability due to it's excellent toughness.

| Auto parts | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| TM4 | 1,000 pcs / corner |

| Competitor’s PVD coated carbide | 500 pcs / corner |

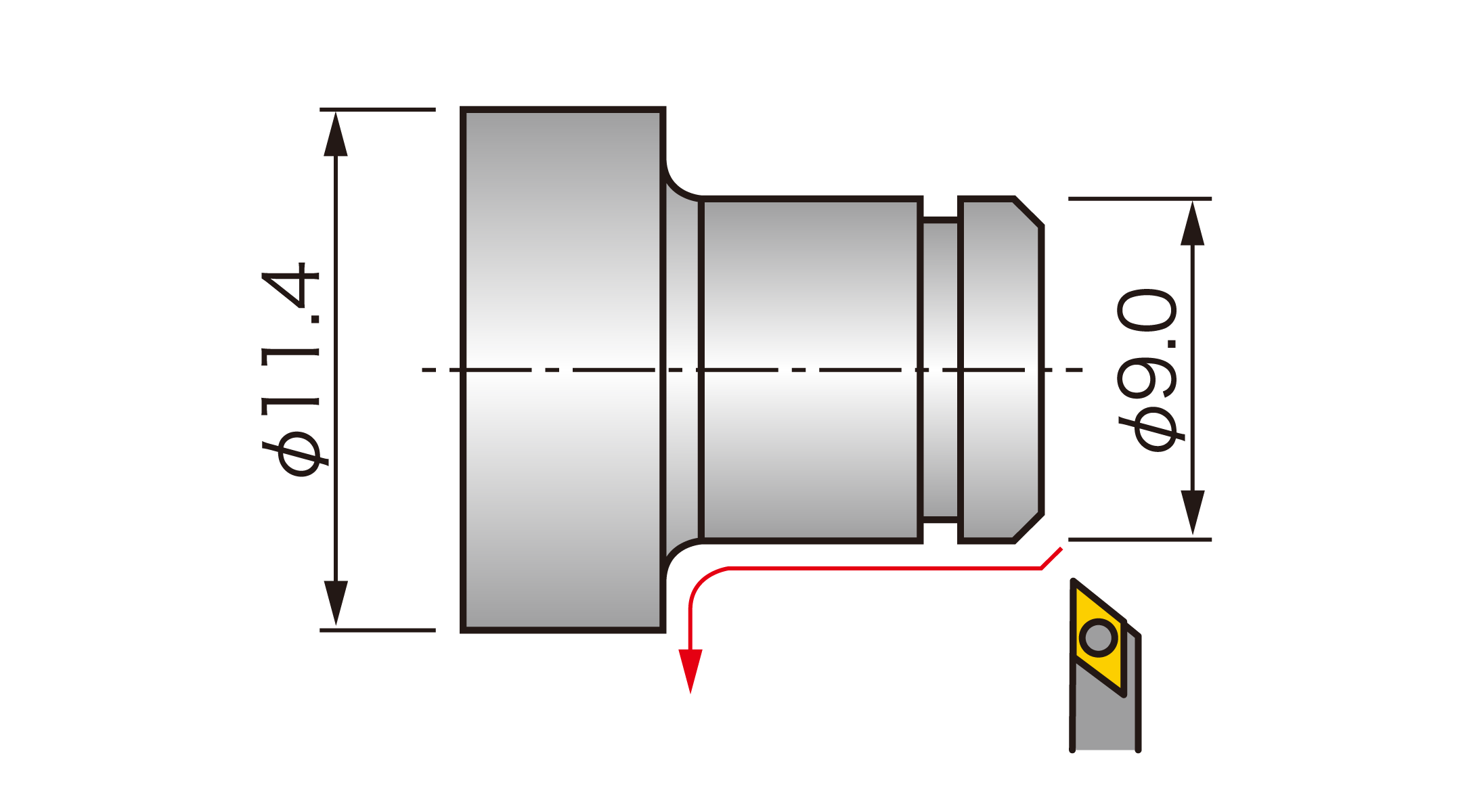

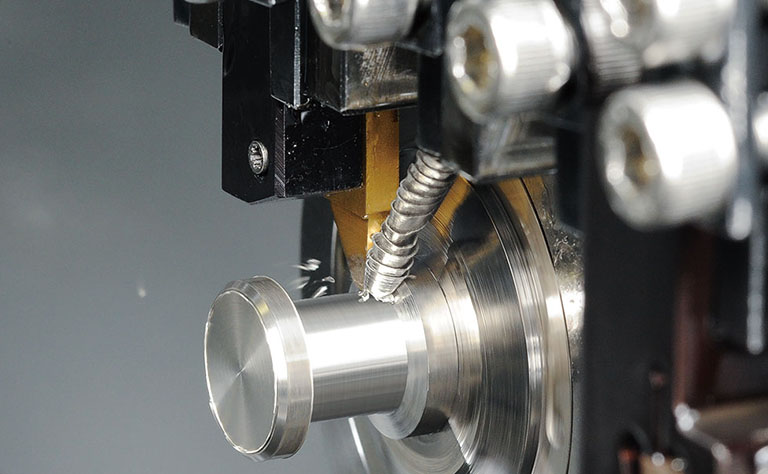

TM4 achieved twice the tool life of the competition during ID boring a 10mm diameter hole.

Tool lineup

Please check product catalog for tooling lineup

Other recommended products

-

CL chipbreakerFor front turning operations | Swiss CNC Lathes

Sharpest molded chipbreaker

-

GX chipbreakerFor grooving | Swiss CNC Lathes

Solves the issue of chips wrapping around workpiece or remaining in the groove

-

TBP/TBPA-BM chipbreakerBack turning | Swiss CNC Lathes

Unique chipbreaker provides excellent chip evacuation

-

CUT DUOCut-off operations for diameters up to 34mm| Swiss CNC Lathes

Highly rigid cut-off tool

Useful information

4 STEP-NTK Cutting Tools Lab for choosing suitable cutting tool for cut-off machining

4 STEP-NTK Cutting Tools Lab for choosing suitable cutting tool for cut-off machining The aspects of "chip control" that you should check when workpiece damage or poor dimensioning are detected during Swiss type CNC automatic lathe machining

The aspects of "chip control" that you should check when workpiece damage or poor dimensioning are detected during Swiss type CNC automatic lathe machining Two Areas to Check When Coaxiality is Not Achieved During Swiss CNC Lathe Machining

Two Areas to Check When Coaxiality is Not Achieved During Swiss CNC Lathe Machining "Two" checkpoints and measures to be checked when "Roundness" does not come out in Swiss-type CNC-automatic lathe machining-NTK Cutting Tools Lab

"Two" checkpoints and measures to be checked when "Roundness" does not come out in Swiss-type CNC-automatic lathe machining-NTK Cutting Tools Lab