GEN3 SeriesDrilling| Coated carbide tips

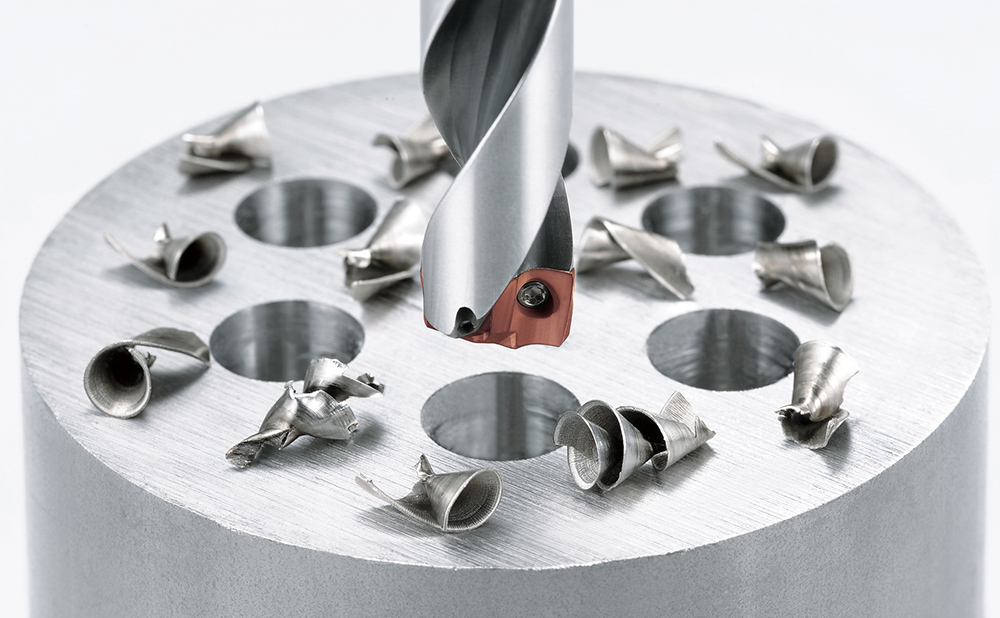

Outstanding performance machining at high speeds

and feeds with good chip control

A coated carbide insert providing efficient drilling with excellent wear resistance and an original chipbreaker shape

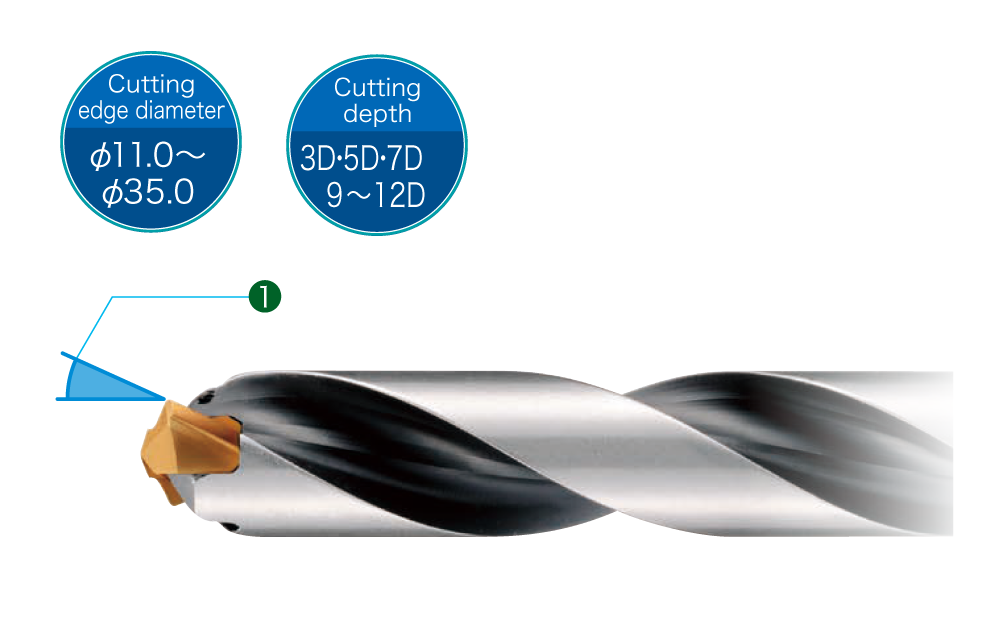

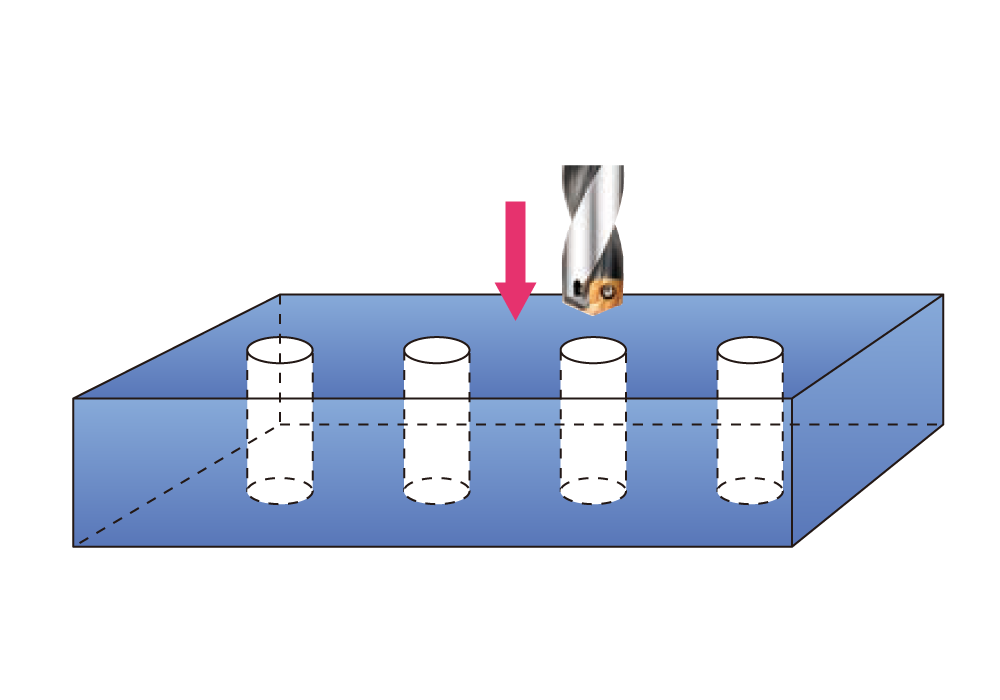

Standard inserts for machining diameters of φ11 to φ35mm

Deep hole drilling up to a maximum machining depth of "12D"

Product video

SCM440 drilling

S17C drilling

Thickwall drilling

Features

- High performance drilling with high speed drilling

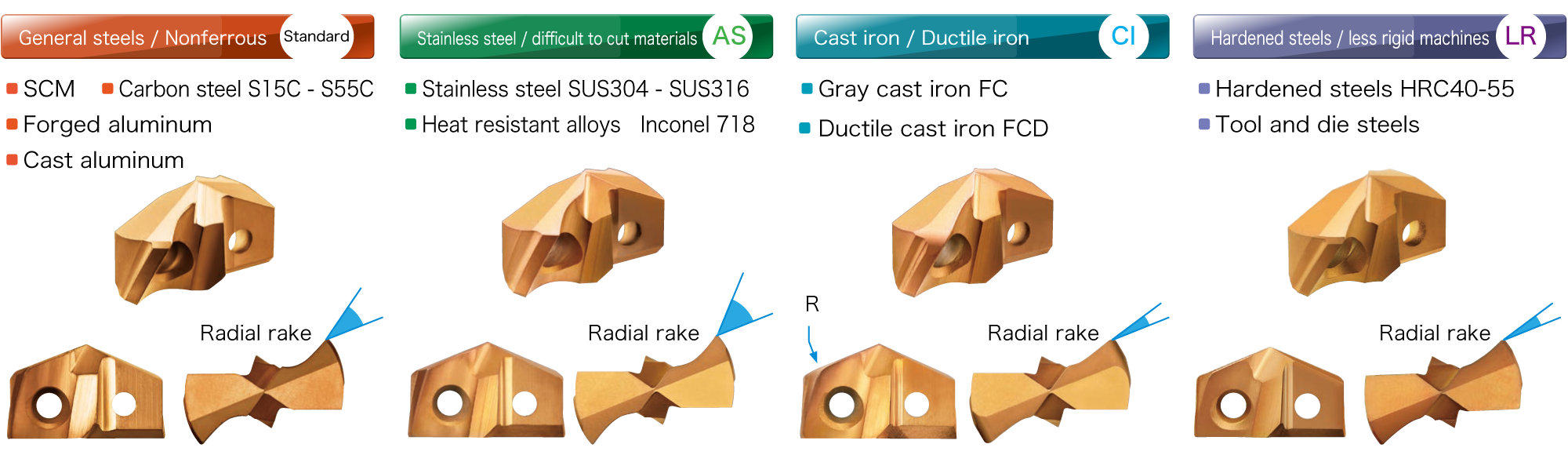

- Lineup of chipbreakers optimized for each work material

- Chips are evacuated with a supply of coolant from the tip of the holder

- No step feed is required to break the chip

Tooling application

Drilling operations in various work materials

Chipbreaker designs provide excellent chip control for each workpiece material group

Corresponding blade diameters and machining depths

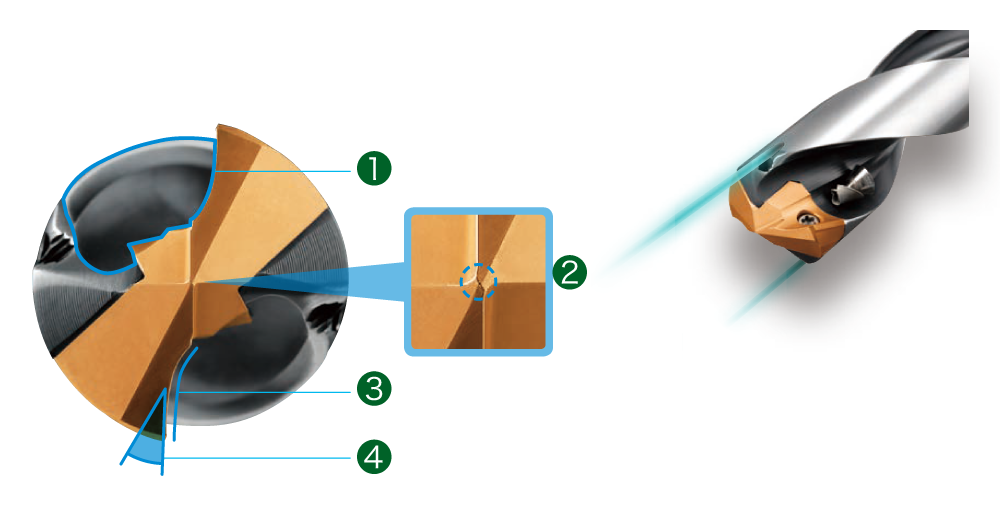

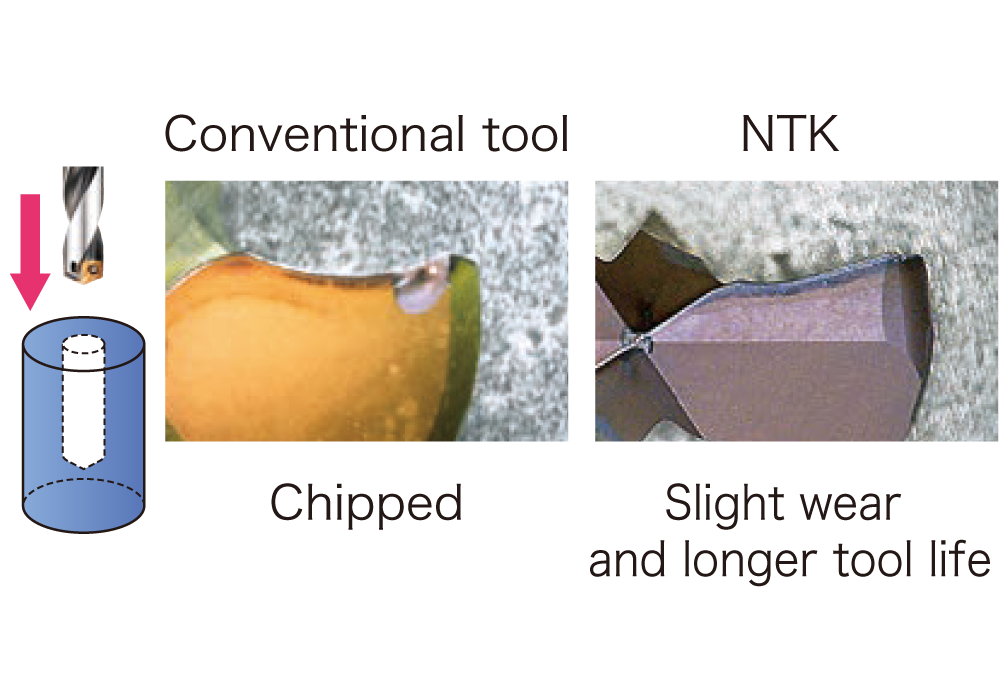

❶ Excellent cutting edge shape provides low cutting force

Stable high-speed machining

❶ Large chip pocket for great control

❷ X thinning improves hole accuracy

❸ Cutting edge design provides low cutting forces

❹ Radial rake angle

Specialized insert edge design for workpiece applications

Scroll the table →

Case study

| Automotive brake part (φ15×87mm, 6D) | |

|---|---|

|

|

|

|

|

|

|

|

|

NTK | 153mm/min |

| Competitor's HSS drill | 41mm/min |

3.7 times higher tool life, a significant improvement to the conventional tooling.

The machine time decreased by eliminating step feed.

| Train part (φ27×135mm, 5D) | |

|---|---|

|

|

|

|

|

|

|

|

|

NTK | 170mm/min |

| Competitor's exchangeable carbide tip drill | 80mm/min |

Machining efficiency more than doubled compared to conventional tooling.

Tool life also doubled compared to the conventional tooling.

Cutting conditions

Tool lineup

Please check product catalog for tooling lineup

Other recommended products

-

Standard GEN2 SeriesDrilling | Powder coated High-speed steel, Coated carbide inserts

Large diameter and ultra-deep machining

Select the chipbreaker based on the workpiece material -

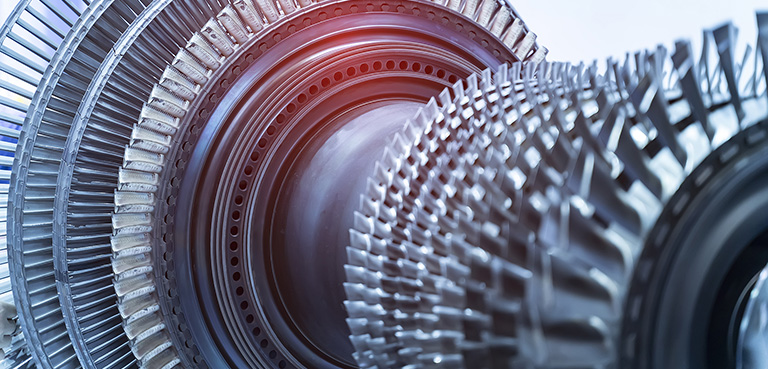

Ceramic and CBN for steel mill applicationsTools for mill roll turning | Ceramic and CBN inserts

High speed performance, longer tool life, and better part surface finish compared to carbide tools

-

WA1/WA5For milling applications | Whisker ceramic for hardened materials

Rapid material removal and long tool life for hard milling

-

SX9Excellent notch and flank wear resistance when roughing gray cast iron|Sialon ceramic

Ceramic grade with the best fracture resistance

Useful information

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕 Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕 Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics

Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics How to Make Ceramic Cutting Tools from Scratch

How to Make Ceramic Cutting Tools from Scratch