Nickel-based alloys are of course mainly composed of nickel.

These alloys are highly resistant to heat and often used for aircraft engine parts that are exposed to high temperature conditions.

Machining of nickel-based alloys is very difficult because it differs greatly from general steel.

Many manufacturers have experience machining nickel-based alloys with cemented carbide tools.

Machining is difficult and the insert edges are quick to wear down.

In this article, we will identify characteristics of nickel-based alloys and introduce effective machining tips.

What are the characteristics of nickel-based alloys ?

What is the difference between nickel-based alloy and carbon steel ?

We compared the characteristics of Inconel 718, nickel-based alloy, with those of carbon steel (S45C).

Numerical values are different and it is easy to see that the materials are quite different from each other.

※ Inconel 718® is a trademark or registered trademark of Special Metals (Special Metals Corporation).

What is the effect of “tensile strength” on cutting tools ?

The tensile strength is the strength of the workpiece against the tensile force expressed by a numerical value.

The higher the value means higher workpiece material strength, that is, the workpiece is viscous and chips tend to be stringy.

Therefore, if chips are not well controlled during machining, they will become tangled with the workpiece and the tooling.

Cutting force increases and machining heat rises at the cutting edge which will cause tool wear or even chipping.

What is the effect of “thermal conductivity” on cutting tools ?

Thermal conductivity is a value that indicates the ease of heat transfer from the workpiece material.

Heat is generated between the tool and the workpiece, due to friction during the machining operation.

Workpiece materials with low thermal conductivity – the heat generated during machining does not easily transfer to the chips and will be concentrated at the cutting edge.

When machining under the same conditions as carbon steel, the material properties of cemented carbide tools change as the temperature of the cutting tool rises.

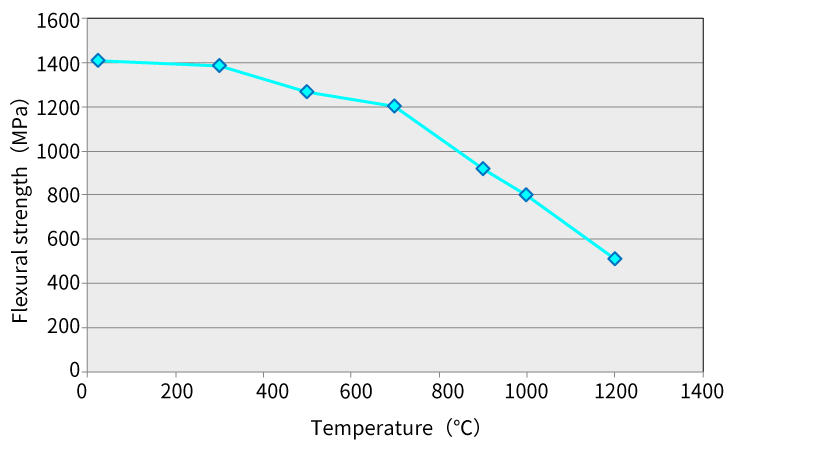

The figure below shows that the hardness and strength of cemented carbide decreased as the temperature increased.

The reduced hardness and strength of the cutting tool makes tool wear more prone to progress or chipping to occur.

This is why carbide tool machining nickel-based alloys experience edge wear and it’s difficult to machine parts.

Summary – Effects of nickel-based alloy machining on cutting tools-

- Cutting force increases due to viscous workpiece material leading to tool wear and chipping due to the increase in heat at the cutting edge.

- Heat generated during machining is concentrated on the cutting tool, resulting in reduced tool hardness and strength.

Although it is the nickel-based alloy that is difficult to cut, there are tools that can machine faster and more efficiently than carbide tools.

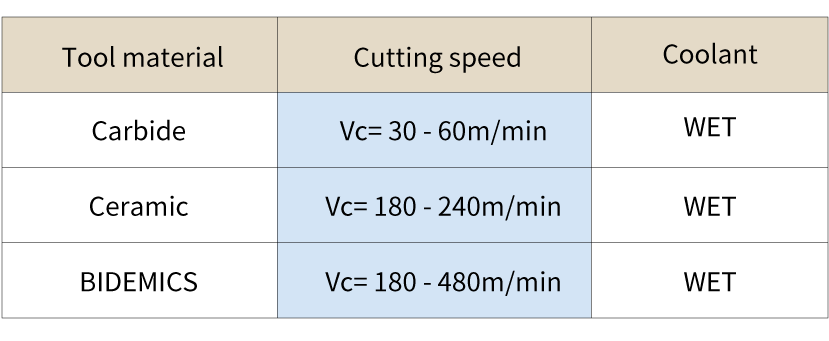

Ceramic tools enable high-speed machining about 10 times faster than cemented carbide

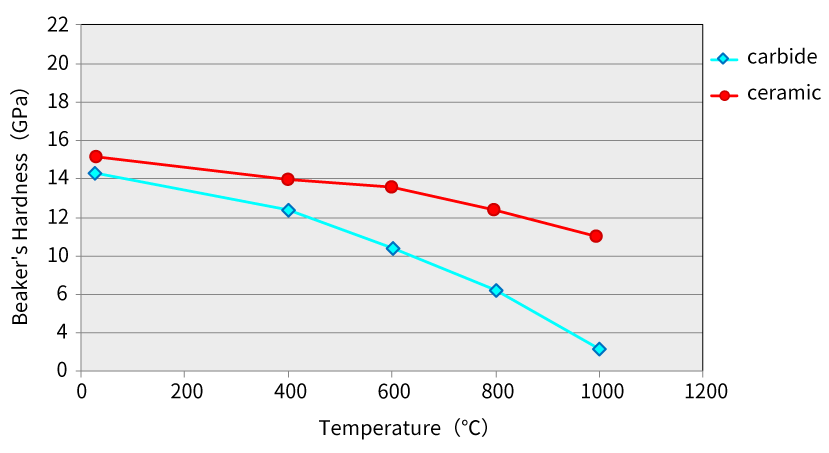

As mentioned in the column “Two reasons why ceramic tools can be used for high-speed machining“, ceramic tools have different characteristics compared to cemented carbide tools.

These include “high temperature hardness” and “high temperature strength”.

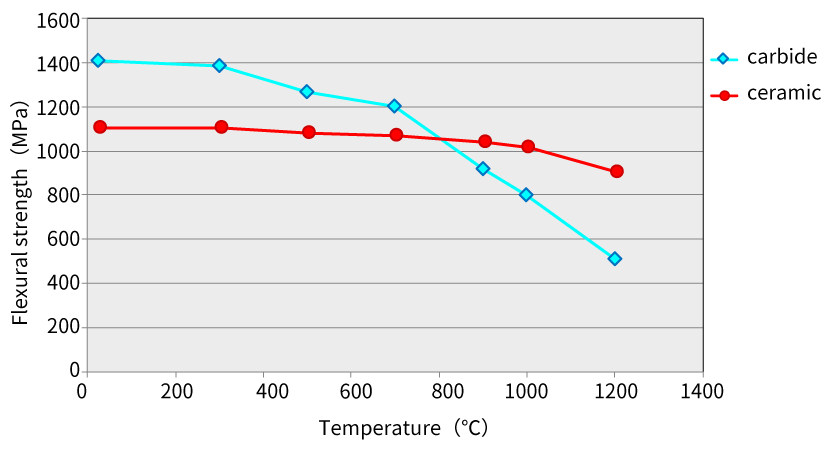

Looking at the figure below, it is clear that even if the temperature rises, the ceramic tool has less of a reduction in hardness and strength compared to carbide.

Ceramic tools are less susceptible to temperature rise, so high-speed machining is possible while maintaining hardness and strength.

[Recommended cutting speed by tool material]

High-speed machining is also achieved by utilizing the characteristics of nickel-based alloys, which change as the temperature rises.

Nickel-based alloy is easy to machine when it exceeds 800°

However, if the temperature exceeds 800°, its strength drops, and machining is much easier.

Taking advantage of the heat resistance of ceramic tools, increasing the cutting speed raises the temperature and allows for machining at the point where the strength of the nickel-based alloy is lower.

※Inconel 718® is a trademark or registered trademark of Special Metals (Special Metals Corporation).

Source: TOOLS NEWS B228J”・EXP-15-E004 2018.10.E(2A, Mitsubishi Materials Corporation

Http://www.mitsubishicarbide.com/application/files/7215/3983/5569/ceramic_b228j.pdf (Ref. 2021-07-26)

Summary – About Nickel-Based Alloy Processing with Ceramic Tools–

- Ceramic tools are less susceptible to temperature rise, enabling high-speed machining that maintains hardness and strength

- High-speed machining raises the temperature and lowers the strength of the nickel-based alloy, enabling freer machining in the temperature range.

We also have a lineup of BIDEMICS, a new material that enables ultra high-speed machining at twice the speed of ceramic tools.

Please be sure to consider NTK Ceramic Tools – Manufacturers having Trouble Machining Nickel-Based Alloys or Manufacturers Who Need Assistance on How to Machine Nickel-Based Alloy for the First Time.

NTK’s official website has been updated with search area.

By simply identifying application conditions you can select the ceramic material that suits the operation and review more product details. Access webpage from the link below.