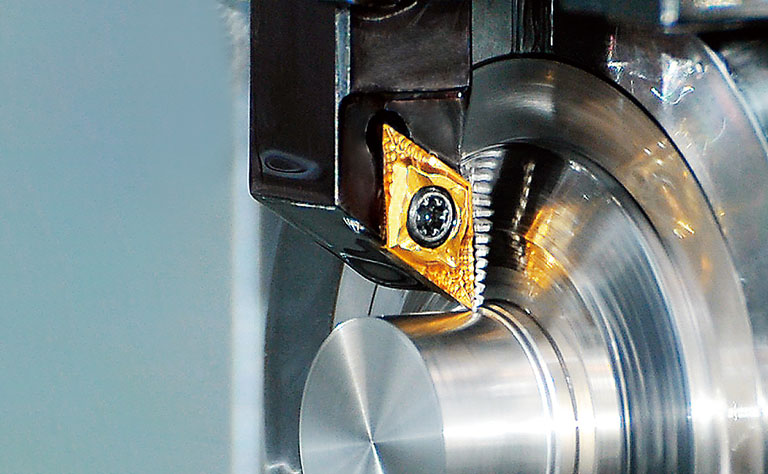

chipbreakerFor front turning operations | Swiss CNC Lathes

chipbreakerFor front turning operations | Swiss CNC Lathes

First recommendation for front turning

Covers a wide range of cutting conditions

Combination of sharpness, toughness, and chip control to handle an extremely wide range of cutting conditions

Product video

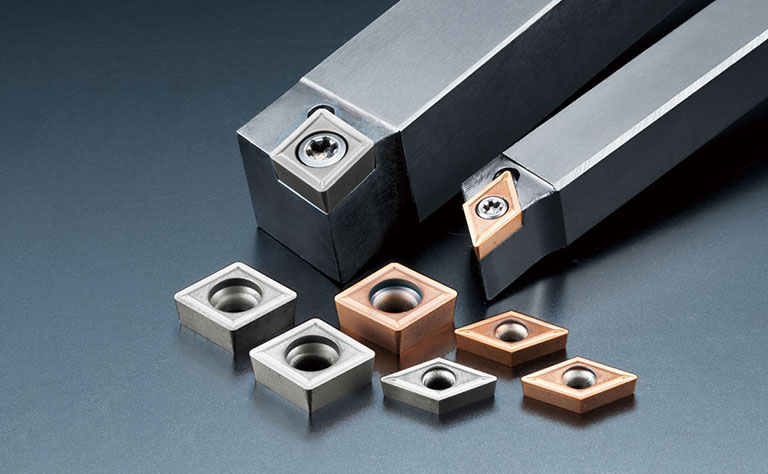

Features

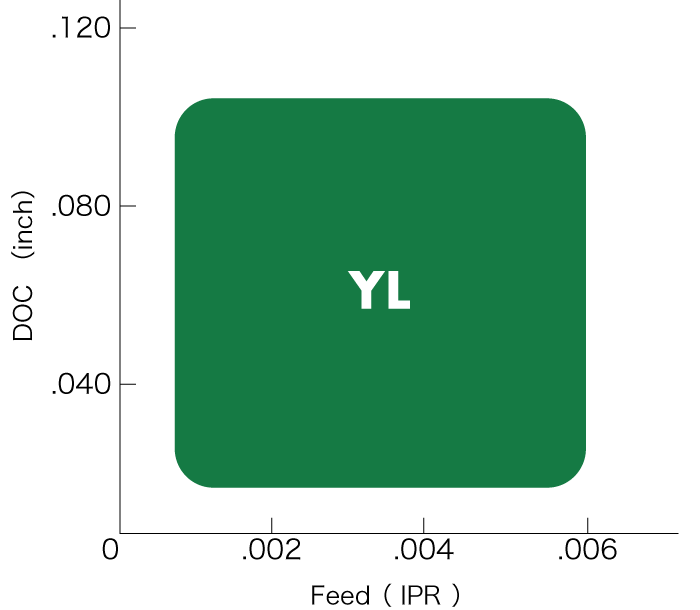

- Range of depth of cut from .020" - .118 "

- Easy to use chipbreaker desing with excellent sharpness, strength and chip control

- Available in many grades to handle a variety of work materials

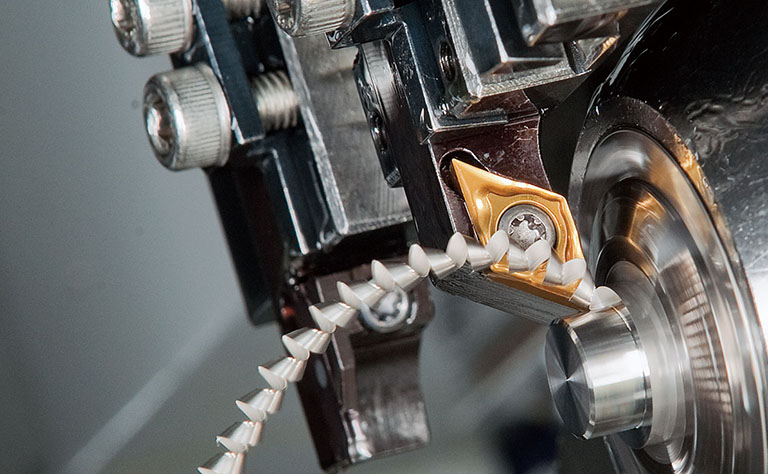

Tooling application

Swiss CNC Lathe front turning operations

YL chip breaker control range

Cutting conditions

Scroll the table →

| Coated grade | Material | Operation type | Cutting speed (SFM) | Feed (IPR) | DOC (inch) |

|---|---|---|---|---|---|

| ST4 | Stainless | OD Turning continuous to interrupted | 150 - 400 | .0008 - .004 | .020 - .118 |

| QM3 | Alloy steel / carbon steel / hardened material | 150 - 400 | |||

| DM4/DT4 | Difficult-to-cut material / titanium alloy / high temp alloys | 100 - 400 | |||

| TM4 | Non-ferrous / aluminum / plastic / general purpose | 150 - 600 |

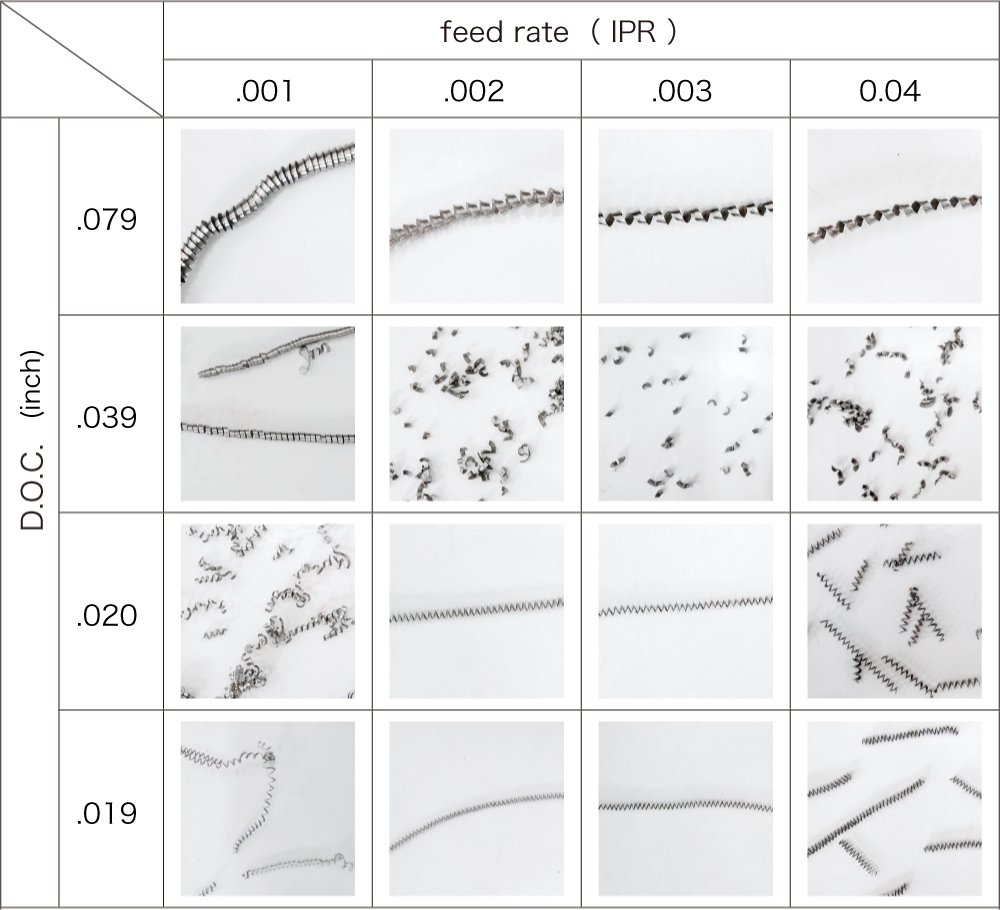

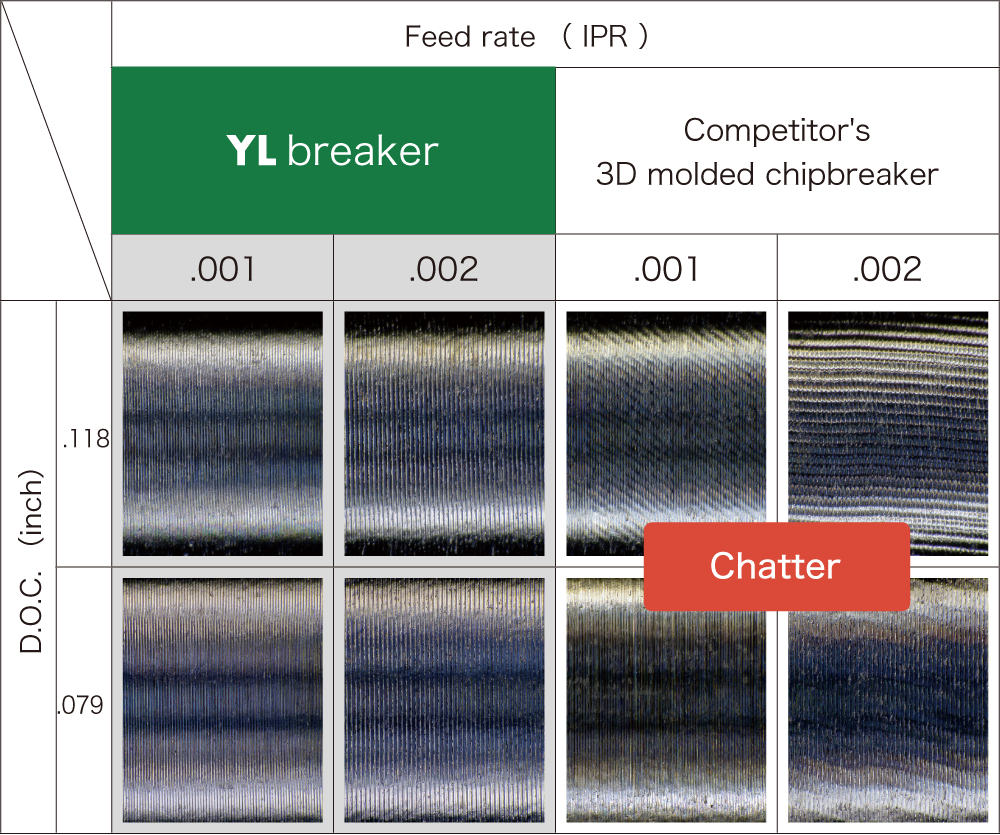

Chip formation and chatter comparison

- [ Cutting condition ]

- Material:304SS φ.63" 260SFM WET

- [ Cutting condition ]

- Material:304SS φ.63" 260SFM f= .002"IPR ap = .078"-.120" WET

Case study

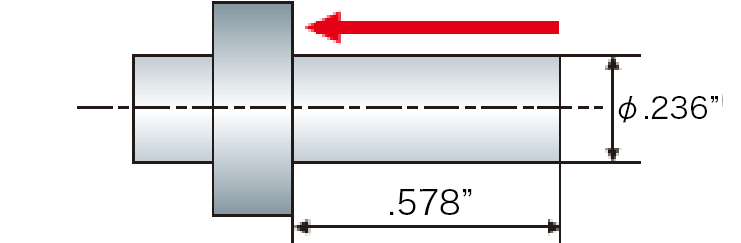

| Pin | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| YL chipbreaker | 3,000 pcs / corner |

| Competitor’s (PVD coated carbide) | 2,000 pcs / corner |

YL had good chip control and longer tool life than competitor's conventional product. Also, achieved stable machining resulting in part dimensional consistancy.

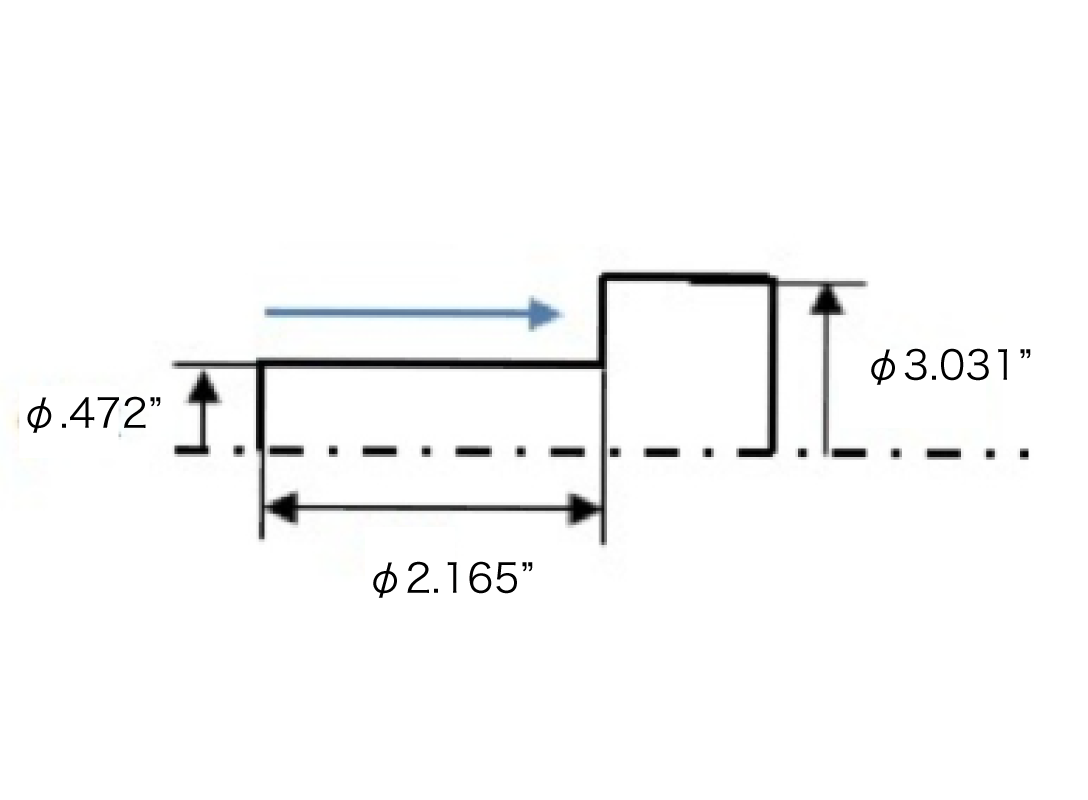

| Auto parts | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| YL chipbreaker + DM4 | 300 pcs / corner |

| Competitor’s PVD coated carbide | 200 pcs / corner |

YL achieved excellent chip control. Longer tool life and larger production run of parts with excellent surface finish compared to company's current insert.

Tool lineup

Please check product catalog for tooling lineup

Other recommended products

-

CL chipbreakerFor front turning operations | Swiss CNC Lathes

Sharpest molded chipbreaker

-

AM3 chipbreakerFor front turning operations | Swiss CNC Lathes

Molded chipbreaker with a balance of cutting edge strength and chip control

-

AM3 chipbreakerFor front turning operations | Swiss CNC Lathes

Chipbreaker for very light depths of cut

-

SPLASH seriesCoolant through toolholders | Swiss CNC Lathes

Extensive selection of styles and sizes

Useful information

4 STEP-NTK Cutting Tools Lab for choosing suitable cutting tool for cut-off machining

4 STEP-NTK Cutting Tools Lab for choosing suitable cutting tool for cut-off machining The aspects of "chip control" that you should check when workpiece damage or poor dimensioning are detected during Swiss type CNC automatic lathe machining

The aspects of "chip control" that you should check when workpiece damage or poor dimensioning are detected during Swiss type CNC automatic lathe machining Two Areas to Check When Coaxiality is Not Achieved During Swiss CNC Lathe Machining

Two Areas to Check When Coaxiality is Not Achieved During Swiss CNC Lathe Machining "Two" checkpoints and measures to be checked when "Roundness" does not come out in Swiss-type CNC-automatic lathe machining-NTK Cutting Tools Lab

"Two" checkpoints and measures to be checked when "Roundness" does not come out in Swiss-type CNC-automatic lathe machining-NTK Cutting Tools Lab