Difficult-to-cut materials | Carbide grade for Swiss CNC lathes

Difficult-to-cut materials | Carbide grade for Swiss CNC lathes

Superior heat resistance

Ideal for difficult materials such as heat resistant alloys and titanium alloys

Stable machining even during high temperature machining conditions

Features

- TiAlN layer protect against insert deterioration from excessive heat

- DT4 has a thin coating. Insert sharpness benefits machining small diameter parts

- DM4 has a thick coating. Its heat and wear resistance suite it well for high load grooving and cut-off operations.

Tooling application

Difficult-to-cut materials especially heat resistant alloys and titanium alloys

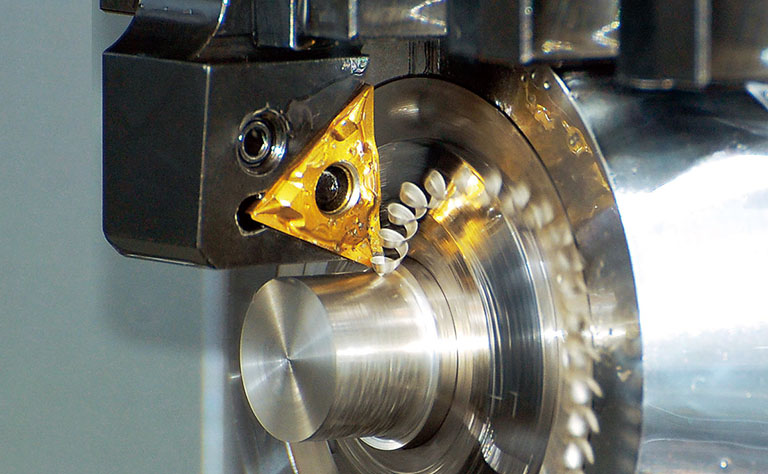

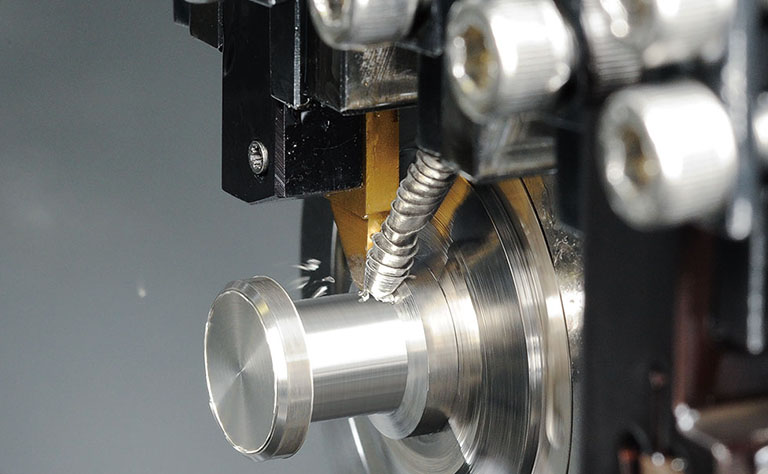

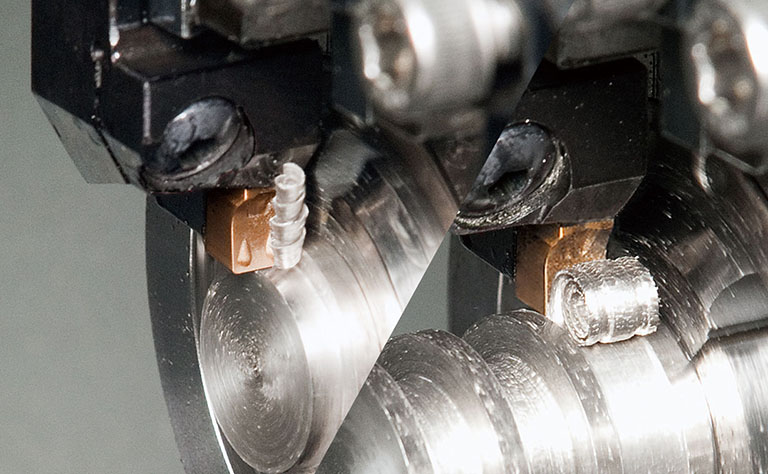

Front turning / Back turning / Grooving / Cut off

DM4 / DT4 comparison chart

Case study

| Cut off | |

|---|---|

|

|

|

|

|

|

|

|

- Insert edge comparison after 800 parts

- DM4 exhibits excellent wear resistance compared to competitor's insert.

| Aircraft parts | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| DM4 | 50 pcs / corner |

| Competitor’s PVD coated carbide | 30 pcs / corner |

DM4 achieved 1.7 times longer tool life compared to the competitor's PVD coated carbide.

| Medical screw | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| DT4 | 400 pcs / corner |

| Competitor’s PVD coated carbide | 250 pcs / corner |

DM4 achieved 1.6 times longer life compared to the competitor's insert.

Tool lineup

Please check product catalog for tooling lineup

Other recommended products

-

UL chipbreakerFor front turning operations | Swiss CNC Lathes

Negative insert developed for Swiss lathes

-

TBP/TBPA-BM chipbreakerBack turning | Swiss CNC Lathes

Unique chipbreaker provides excellent chip evacuation

-

SCRUM DUOFor grooving| Swiss CNC lathes / Conventional CNC lathes

Highly rigid holder design

-

SPLASH seriesCoolant through toolholders | Swiss CNC Lathes

Extensive selection of styles and sizes

Useful information

4 STEP-NTK Cutting Tools Lab for choosing suitable cutting tool for cut-off machining

4 STEP-NTK Cutting Tools Lab for choosing suitable cutting tool for cut-off machining The aspects of "chip control" that you should check when workpiece damage or poor dimensioning are detected during Swiss type CNC automatic lathe machining

The aspects of "chip control" that you should check when workpiece damage or poor dimensioning are detected during Swiss type CNC automatic lathe machining Two Areas to Check When Coaxiality is Not Achieved During Swiss CNC Lathe Machining

Two Areas to Check When Coaxiality is Not Achieved During Swiss CNC Lathe Machining "Two" checkpoints and measures to be checked when "Roundness" does not come out in Swiss-type CNC-automatic lathe machining-NTK Cutting Tools Lab

"Two" checkpoints and measures to be checked when "Roundness" does not come out in Swiss-type CNC-automatic lathe machining-NTK Cutting Tools Lab