A Swiss type CNC automatic lathe and a CNC lathe, they are similar lathe machines,

but did you know they are completely different?

In this edition, we will introduce the 4 differences between the cutting tools used based on the mechanical structure of Swiss CNC automatic lathes and CNC lathes.

What is the difference between a “Swiss CNC automatic lathe” and a “CNC lathe”?

- forte:

- We are good at machining a large amount of parts from bar stock material. It is automatically continuously machined, like candy, until the material is exhausted.

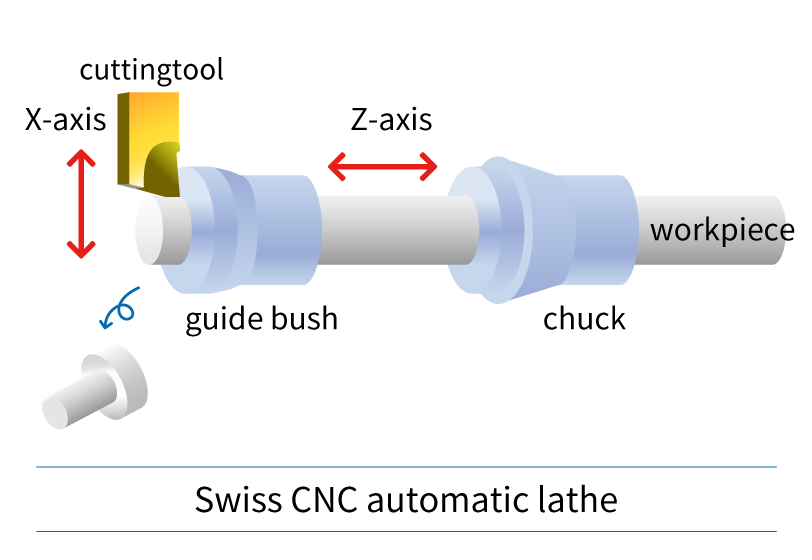

- Machining is performed by moving the cutting insert on the X axis and the workpiece on the Z axis.

- Since the guide bushing supports the workpiece and machining is done near the guide bushing, which eliminates workpiece “vibrations” or “deflections”. Therefore, the machine is perfect for manufacturing thin and long workpieces. It is ideal for machining parts with tight tolerance requirements, such as motor parts.

- The material diameters of as small as “φ1.0 mm” (.040 inch) can also be machined successfully.

- forte:

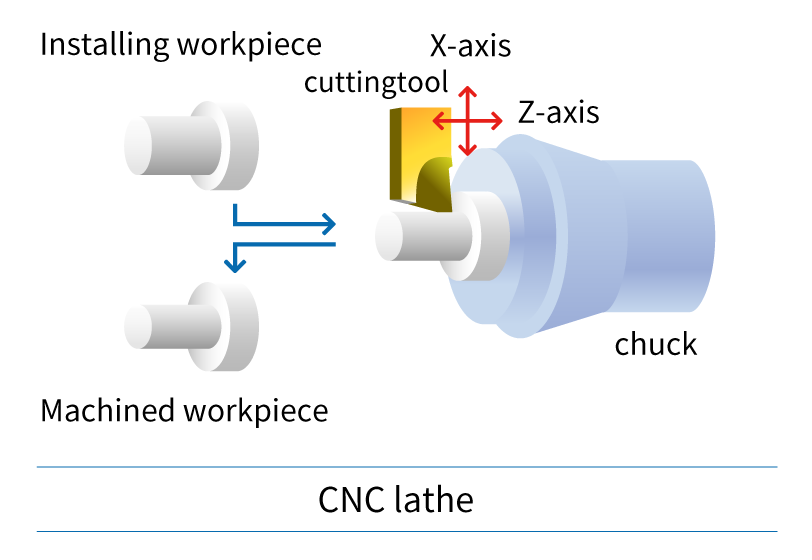

- The material is grasped one by one with a chuck and machined. The workpiece is installed and removed by a person or robot.

- The cutting tool machines moves on the X axis and the Z axis.

- Because it chucks according to the shape of the workpiece, the range of the parts that can be processed is wide.

- It is possible to machine parts that have been shaped to some extent, such as after forging and casting materials.

Swiss CNC automatic lathe & CNC lathe: Since the machine structure, workpiece, and size are different, it is important to select the cutting tool accordingly. Now let's take a look at the features of cutting tools used in CNC automatic lathes.

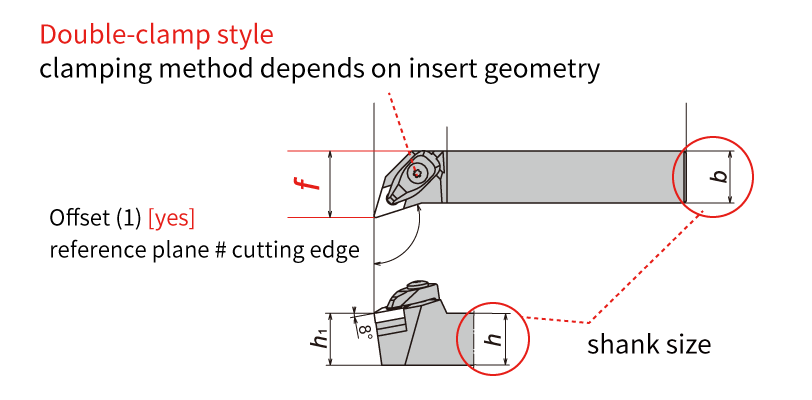

Difference 1. Holder

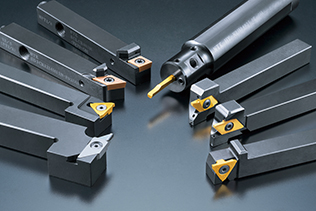

The holder is an important component for achieving chip performance. I will explain the difference between the holder used on a Swiss type CNC automatic lathe and a CNC lathe.

Holders for Swiss CNC Automatic Lathe

- Common shank sizes are: 8mm, 3/8″, 10mm, 12mm, 1/2″, 16mm, 5/8″, 20mm, and 3/4″ which are smaller than holders for a standard CNC lathe machines.

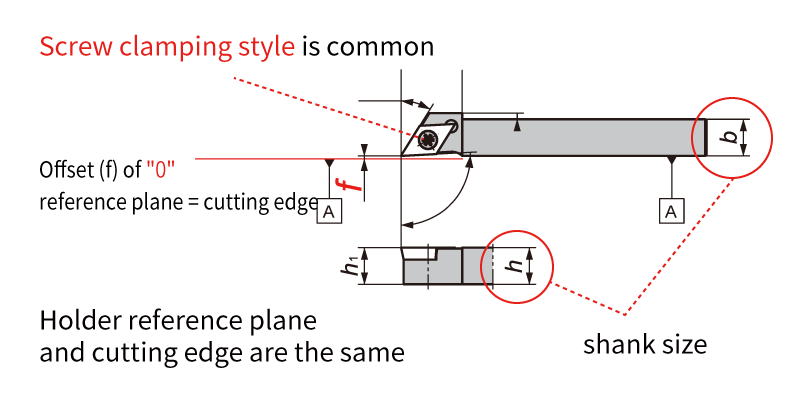

- The screw clamp type is suitable for small holders and small inserts, due to its simple structure. Also, the insert clamping force is strong which ensures excellent cutting edge positioning accuracy. This is ideal for highproduction machining of precision parts.

- The offset is often “0”, which is means the holder reference surface = cutting edge position.

Difference 2. Insert geometry: Positive inserts and Negative inserts

CNMG... DNMG...: If you are familiar with machining on CNC lathes, you likely know about insert geometries. The Swiss type CNC automatic lathe is the same type of lathe, but if you are thinking of machining with the same insert, be careful. Inserts such as "CNMG /CNGA..." and "DNMG/DNGA ..." used on CNC lathes have many corners, and the cutting edge is honed or chamfered (edge preparation) and have excellent cutting edge strength. Therefore, these inserts are ideal for shearing the workpiece material. On the other hand, when a negative insert such as "CNMG/CNGA..." is used on a Swiss type CNC automatic lathe, cutting resistance tends to be high and "chatter" and "work deflection" occur. We recommend using a "positive style" for Swiss CNC automatic lathes.

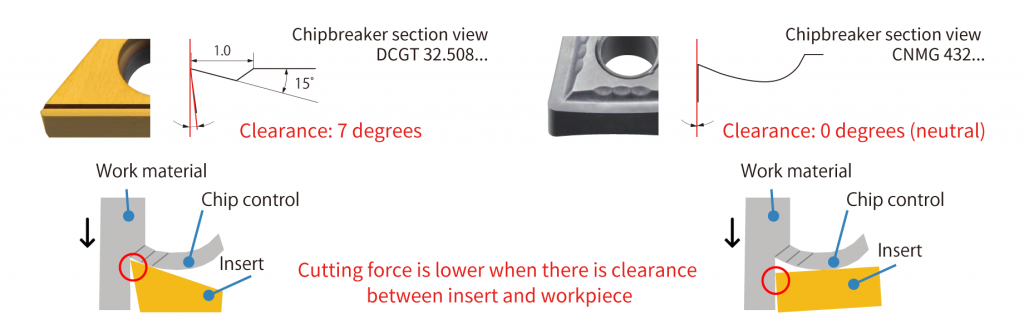

Swiss-type CNC automatic lathes machine workpieces that are smaller in diameter and require higher precision than machining on a CNC lathes. High cutting resistance causes “vibration” and “dimensional defects”, so using a “positive insert” with a relief angle to reduce cutting resistance and achieve stable machining.

As shown above, the larger the clearance angle (relief), the smaller the area where the tool touches the workpiece. This reduces cutting resistance.

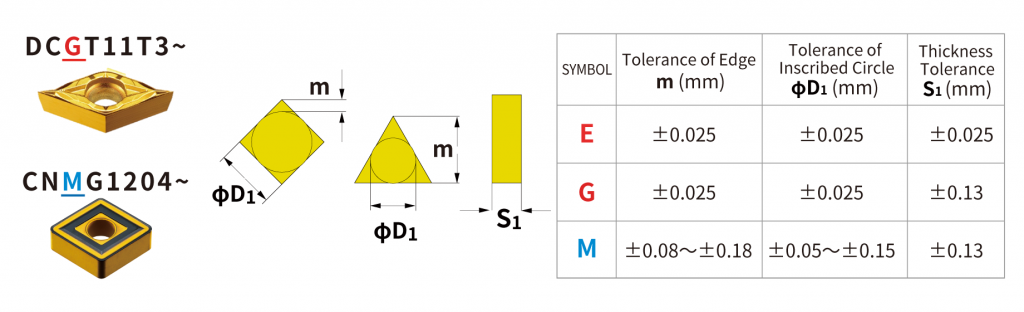

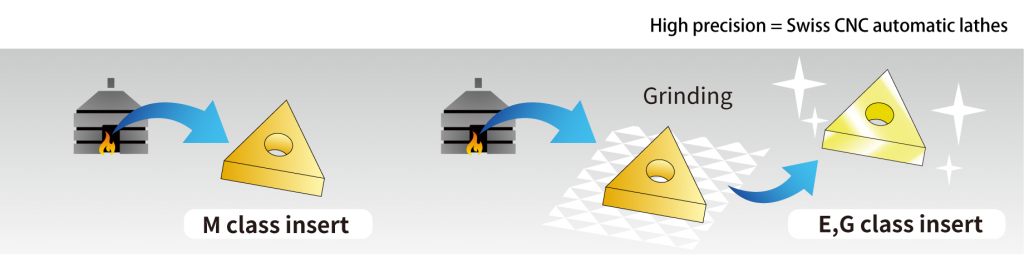

Difference 3. Insert tolerance: G-class and M-class

The ISO insert designation includes a tolerance class. I will discuss the difference in insert tolerance classes for Swiss type CNC automatic lathes and CNC lathes.

The table above compares the “M” class commonly used on CNC lathes with the “G” class and “E” class commonly used on Swiss SNS automatic lathes. The 3rd letter in the insert part description identifies the tolerance class. Insert such as CNMG… and DNMG… have an M class tolerance. On the other hand, inserts such as DCGT… and CCGT… have a G-class tolerance.

As shown in the table, the insert tolerance is very different between the “G” and “M” class. Corner length (m) and insert IC (dia. D1) tolerance affect the accuracy of the cutting edge position, or workpiece dimensions. Thickness tolerance (S1) affects the height of the cutting edge. Swiss-type CNC automatic lathes require high precision machining of small diameter workpieces, so “G-class” or “E-class” with higher tolerance than M-class are used. Also, the upper and lower insert surfaces of G-class and E-class inserts are polished and the outer edges are ground with high accuracy which achieves excellent sharpness.

For Swiss CNC automatic lathes, it is strongly recommended to use inserts with “G-grade” and “E-class” tolerances.

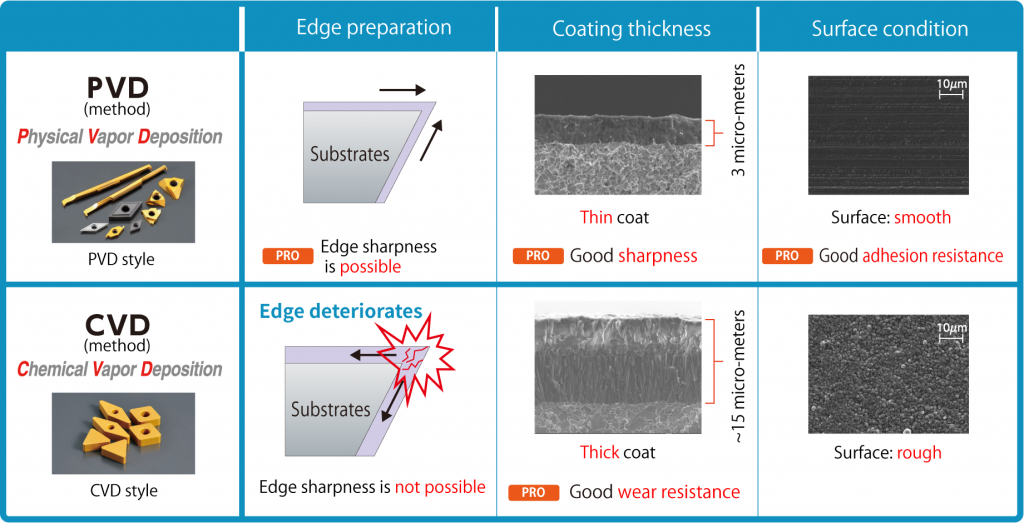

Difference 4. Coatings types: PVD vs. CVD

Coating is an important factor in determining the performance of tools and the quality of workpieces. There are two main types of coatings - CVD and PVD. Which coating is suitable for Swiss CNC automatic lathes?

Inserts like “CNMG” and “DNMG” used on CNC lathes are generally CVD coated. CVD coatings can be thick films compared to PVD coatings and have excellent abrasion resistance. But, because it is a thick film coating, it is easy to cause deterioration and there is a disadvantage of a rough coating surface.

Swiss-type CNC automatic lathe machining requires high precision, sharpness is important, so PVD coatings are more suitable due to thin film coatings achieving sharp edges.

As shown in the figure above, PVD coatings have excellent sharpness, dimensional stability, and welding resistance making it the ideal coating style for Siwss-type CNC automatic lathes.

Do you still have questions about the difference between tooling used for a Swiss type CNC lathe and traditional CNC lathe?

NTK offers a large lineup of tools specialized for CNC automatic lathes. If you are having issues machining,

please consider it our tools and contacting us for technical advise.