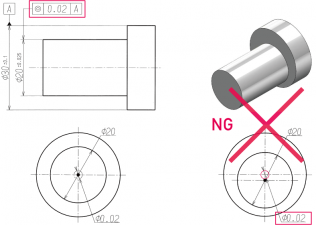

When I machined the workpiece in the drawing, shown below, the part was No Good.

You see that the part does not meet the Coaxiality ![]() requirements on the drawing.

requirements on the drawing.

What should be done to meet the Coaxiality?

Coaxiality is very important in Swiss-type CNC automatic lathe machining, where “high precision” parts are required.

This time, we will discuss the two points to check when coaxiality requirements are not met in Swiss type CNC automatic lathe machining.

Checkpoint when “Coaxiality” does not occur: ① Machining Axis

Confirm if the machining is performed on the same axis.

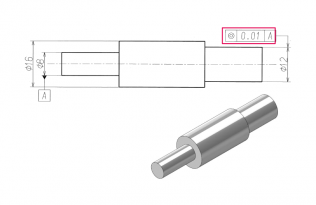

The following is an example of machining a workpiece with “coaxiality tolerance” as shown in the figure.

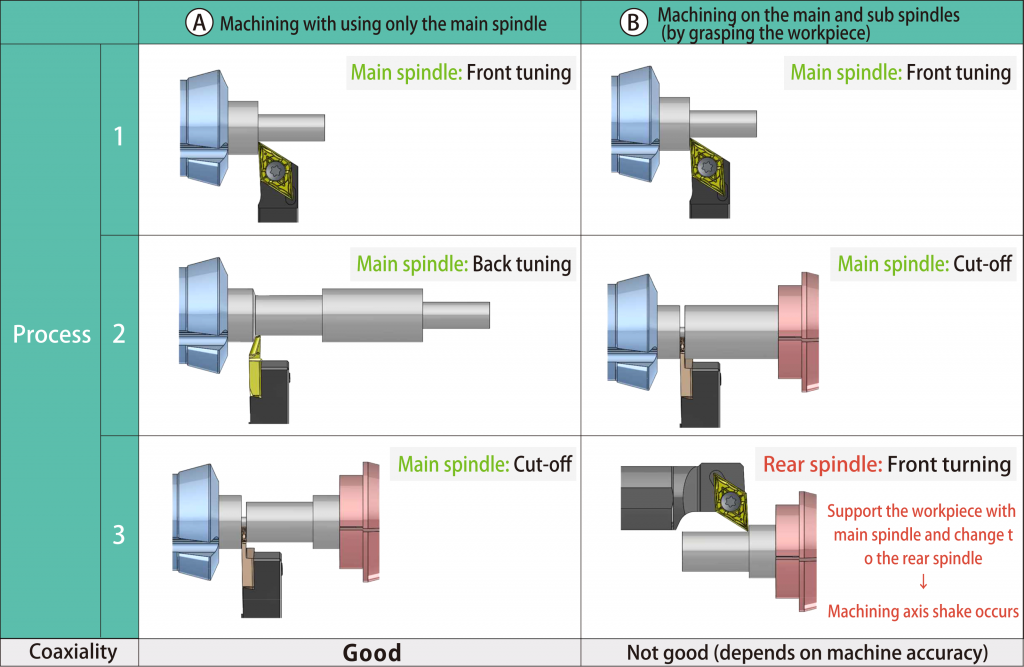

There are two possible machining methods.

- A. Machining with using only the main spindle

- B. Machining on the main and sub spindles (by grasping the workpiece)

In method A. Machining only on the main spindle results in good coaxiality because all the operations are performed on the same axis.

In method B. Separate machining is done on the main and sub spindles; the workpiece is grabbed and changed in the middle of the machining process.

As a result, there are cases where the machining axis is shaken and “coaxiality” is not good.

→ Counter measure 1: Due to the machining principle of the lathe, “coaxiality” can be obtained in many cases if machining is performed on the same axis.

When coaxiality is required, use the same axis for machining.

Checkpoint when “coaxiality” does not occur: ② Processing method

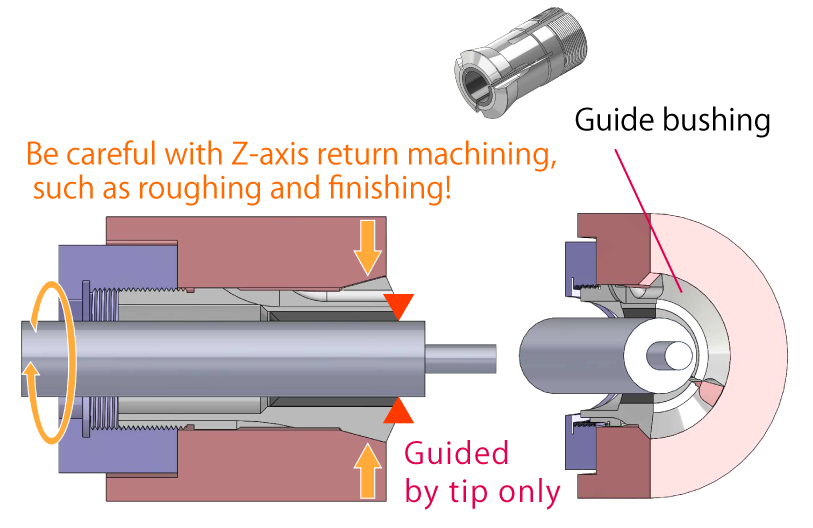

Confirm whether there is a machined point that is pulled back into the guide bushing.

The figure shows the structure of the guide bushing.

The workpiece is actually only supported at the tip of the guide bushing.

In other words, even within the range of the guide bush gripping length, the workpiece is not strictly guided.

Therefore, care must be taken when returning the Z-axis (workpiece), such as rough and finish machining.

Why do we need to be careful ?

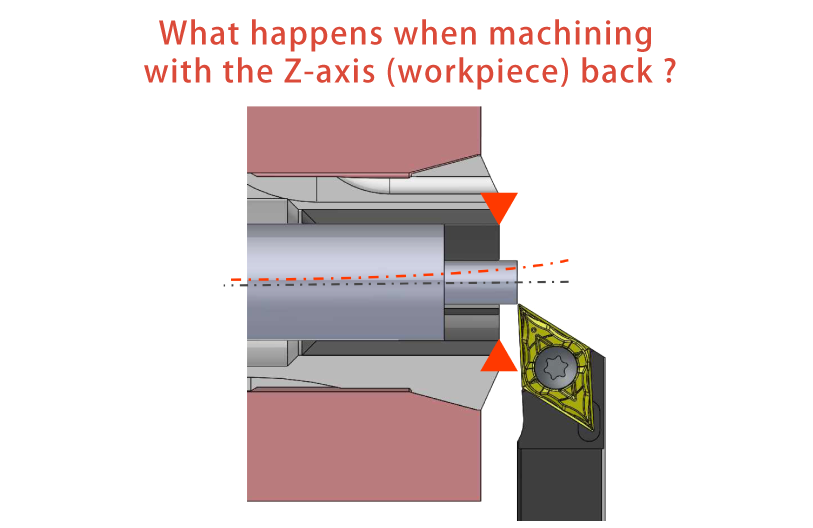

In the figure, the Z-axis (workpiece) is returned to the guide bushing for machining.Since the workpiece is no longer held by the tip of the guide bushing, there is a possibility that the machining axis will be blurred and coaxiality will not be produced due to cutting force when machining.

Therefore, it is important not to return the workpiece inside of the guide bush after machining is performed.

→ Countermeasure 2. In many cases, “coaxiality” is obtained when machining with the work piece firmly supported by the guide bushing.

Use a Shifted Holder and DS Holder where coaxiality is required.

Shifted holder

Shifting of the cutting edge prevents the workpiece from entering the guide bush.

As a result, machining while securely guiding the workpiece is possible.

DS holder

Work pieces can be prevented from being pulled back into the guide bushing by machining from the front side and utilizing the tool station for face machining.

As a result, machining while securely guiding the workpiece is possible.

In addition, the coaxiality is further improved by fixing the workpiece material and machining with only the DS holder.

We hope you found the information on achieving coaxiality to be useful for effectively machining parts on you Swiss-type CNC automatic lathe.

NTK offers a wide range of cutting tools specialized for Swiss-type CNC automatic lathe machining.