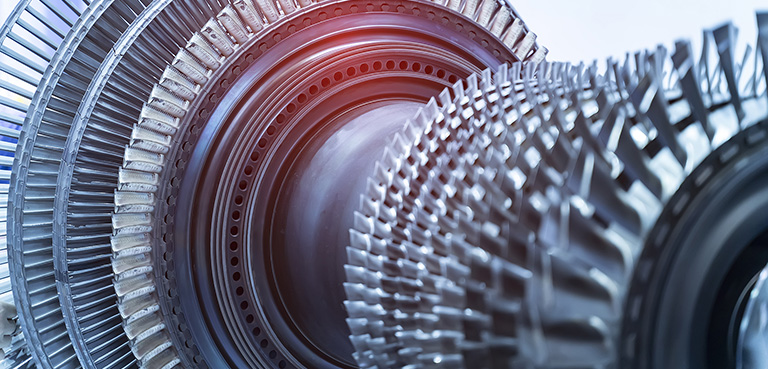

Roughing gray cast & ductile cast iron / CVD coated carbide

Roughing gray cast & ductile cast iron / CVD coated carbide

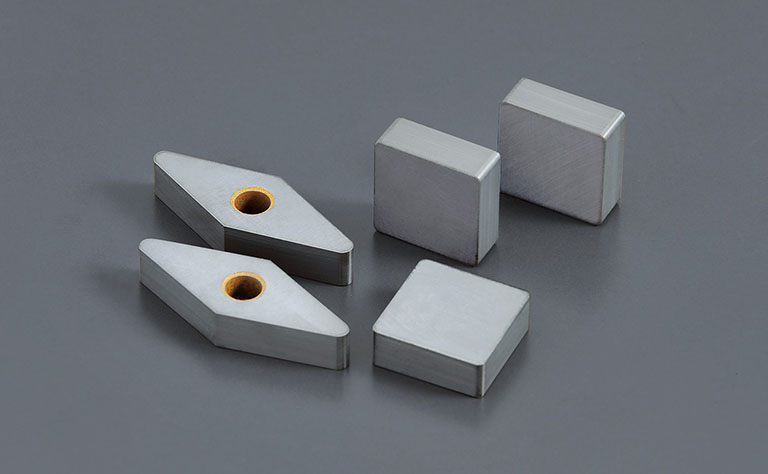

CVD coated carbide grade ideal for roughing

Highly efficient and stable machining even during low cutting speed conditions

Outstanding wear resistance at cutting speeds of 1000 SFM

Features

- Ideal for roughing of gray and ductile cast iron

- High degree of wear resistance and stable machining due to thick laminated TiCN + Al2O3 coating

- Excellent adhesion resistance with the uniquely smooth rake surface treatment

Tooling application

Gray cast iron/Ductile cast iron

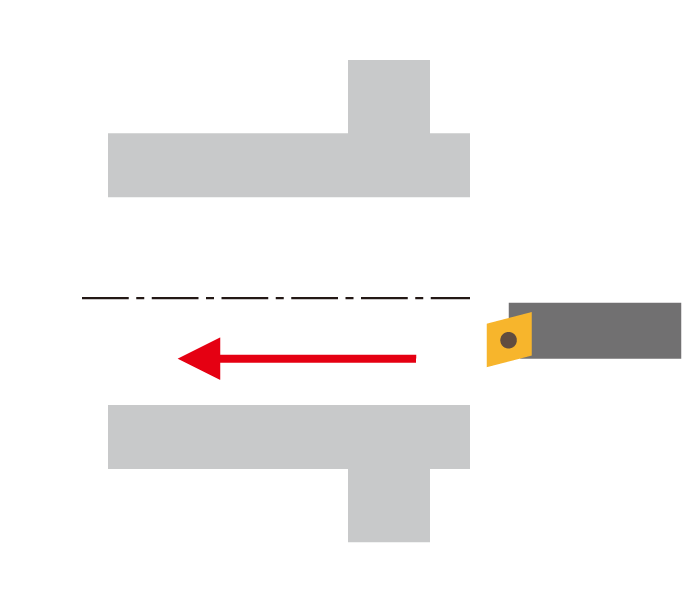

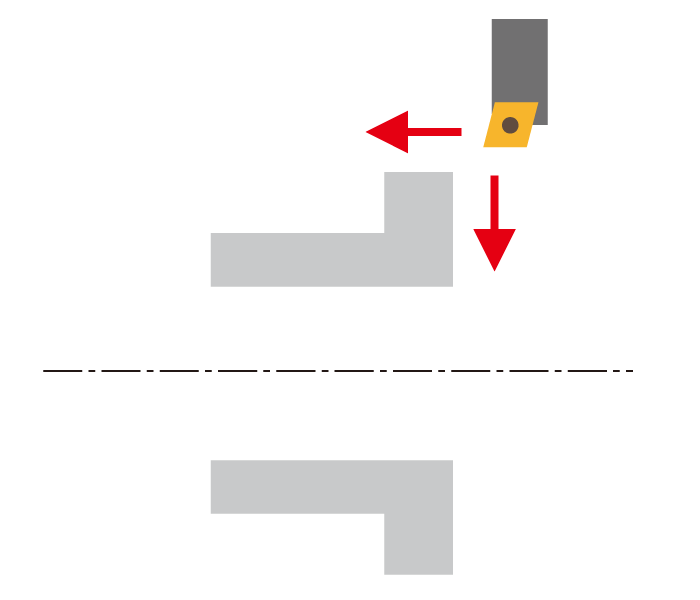

Roughing with scale

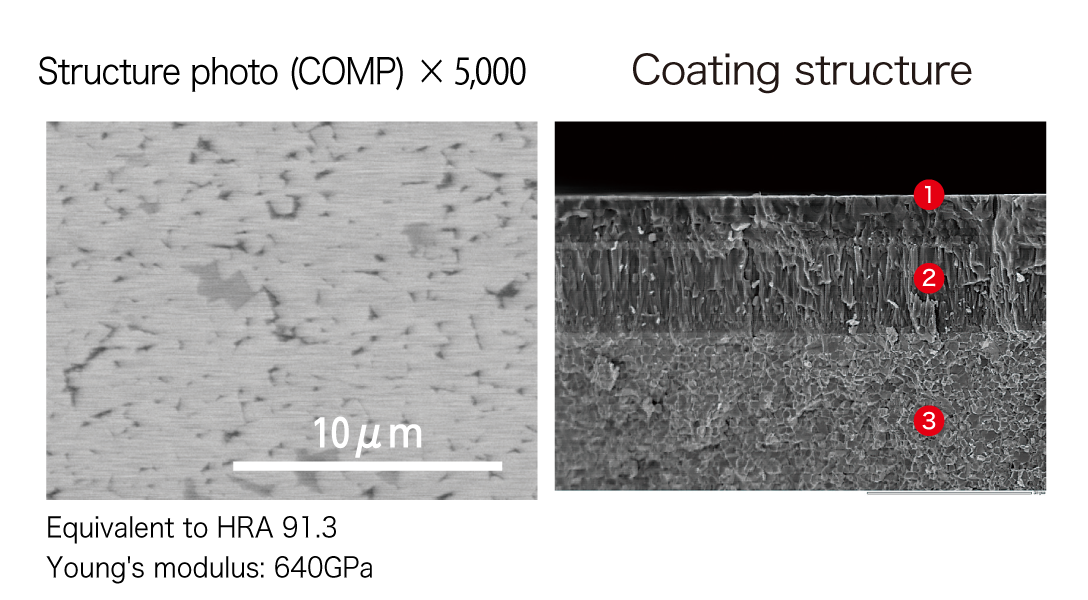

Coating composition

- ① A very smooth layer of fine grain Al2O3

② Fine column shaped grain TiCN layer

③ Ultra - hard cemented carbide base material

Cutting conditions

Scroll the table →

| Grade | Material | Operation type | Machining | Cutting speed (SFM) | Feed(IPR) | DOC(inch) | Coolant |

|---|---|---|---|---|---|---|---|

| CP1 | Gray cast iron/Ductile cast iron | Turning | Roughing with scale, Rough to semi-finish machining | 300 - 1000 | .008 - .016 | - .197 | WET |

Case study

| ID boring of housing part | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

| CP1 | 110 pcs / corner |

|

| Competitor’s CVD coated carbide | 50 pcs / corner |

|

| OD machining of water pipe part | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

| CP1 | 60 pcs / corner |

|

| Competitor’s CVD coated carbide | ||

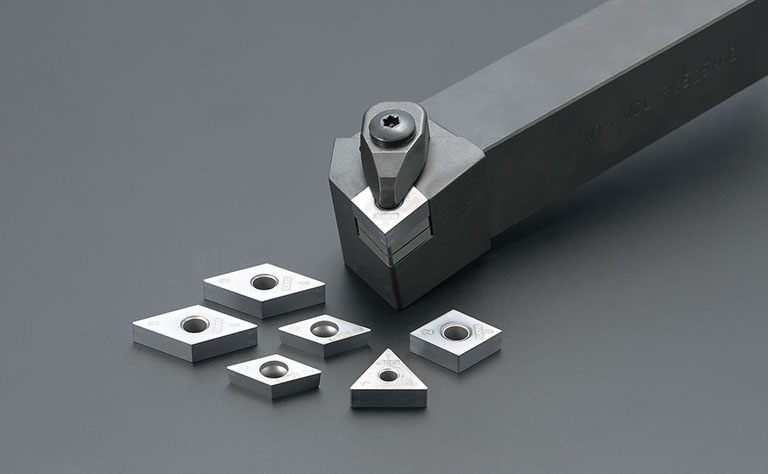

Tool lineup

Please check product catalog for tooling lineup

Other recommended products

-

SX6Exceptional wear resistance for rough machining of gray cast iron| Silicon nitride ceramic

First recommendation for roughing gray cast iron

-

SX9Excellent notch and flank wear resistance when roughing gray cast iron|Sialon ceramic

Ceramic grade with the best fracture resistance

-

SP9Roughing to finishing of ductile cast iron & gray cast iron| Coated Silicon Nitride Ceramic

Covers roughing to finishing operations

-

B5K/B52CBN grades for finishing ductile cast iron| Coated (B5K) / Un-coated (B52)

Best CBN grades for high-speed finishing of ductile cast iron

Useful information

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕 Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕 Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics

Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics How to Make Ceramic Cutting Tools from Scratch

How to Make Ceramic Cutting Tools from Scratch