SeriesMilling cutter for machining aluminum parts| PCD inserts

SeriesMilling cutter for machining aluminum parts| PCD inserts

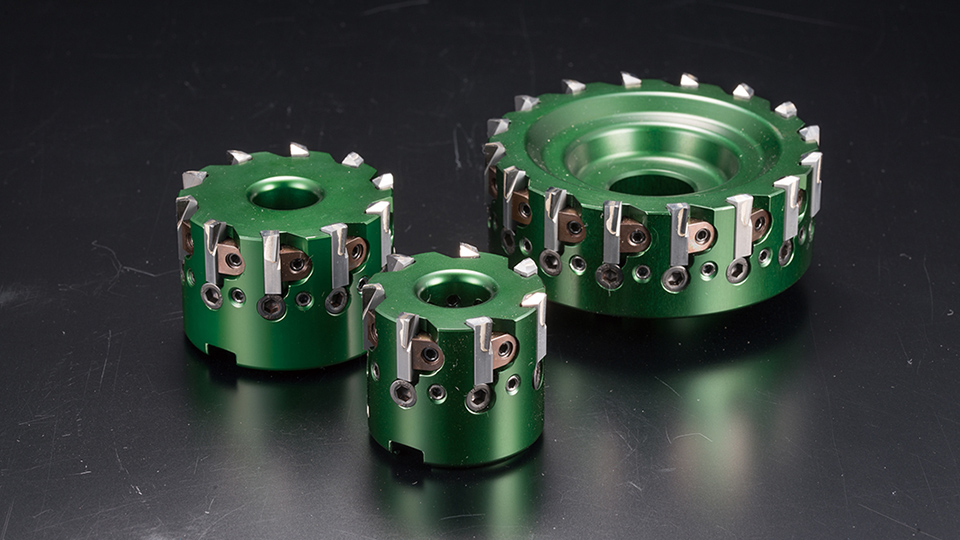

Maximum insert count for increased productivity

φ4.921" diameter cutter has 22 inserts achieving outstanding machining performance

φ1.969" to φ4.921" diameter lineup

Obtains 1.5 times better productivity than the competition

Product video

Features

- Highly efficient machining is achieved with more inserts

- Lightweight aluminum cutter body to accommodate ATC weight limitations

*ATC = automatic tool changer on CNC

Tooling application

Milling aluminum

Cutting conditions

Scroll the table →

| ●1st Recommendation 〇2nd Recommendation |

||||||

| Grade | Material | Cutting speed (SFM) | Feed(IPR) | DOC(inch) | DRY | WET |

|---|---|---|---|---|---|---|

| PD1 | Aluminum alloy (SI≦13) | 3000 - 10000 - 17000 | .0020 - .0047 - .0079 | ~ .25 | 〇 | ● |

| PD1 | Aluminum alloy (Si≧13) | 1000 - 2000 - 3000 | .0020 - .0047 - .0079 | ~ .25 | 〇 | ● |

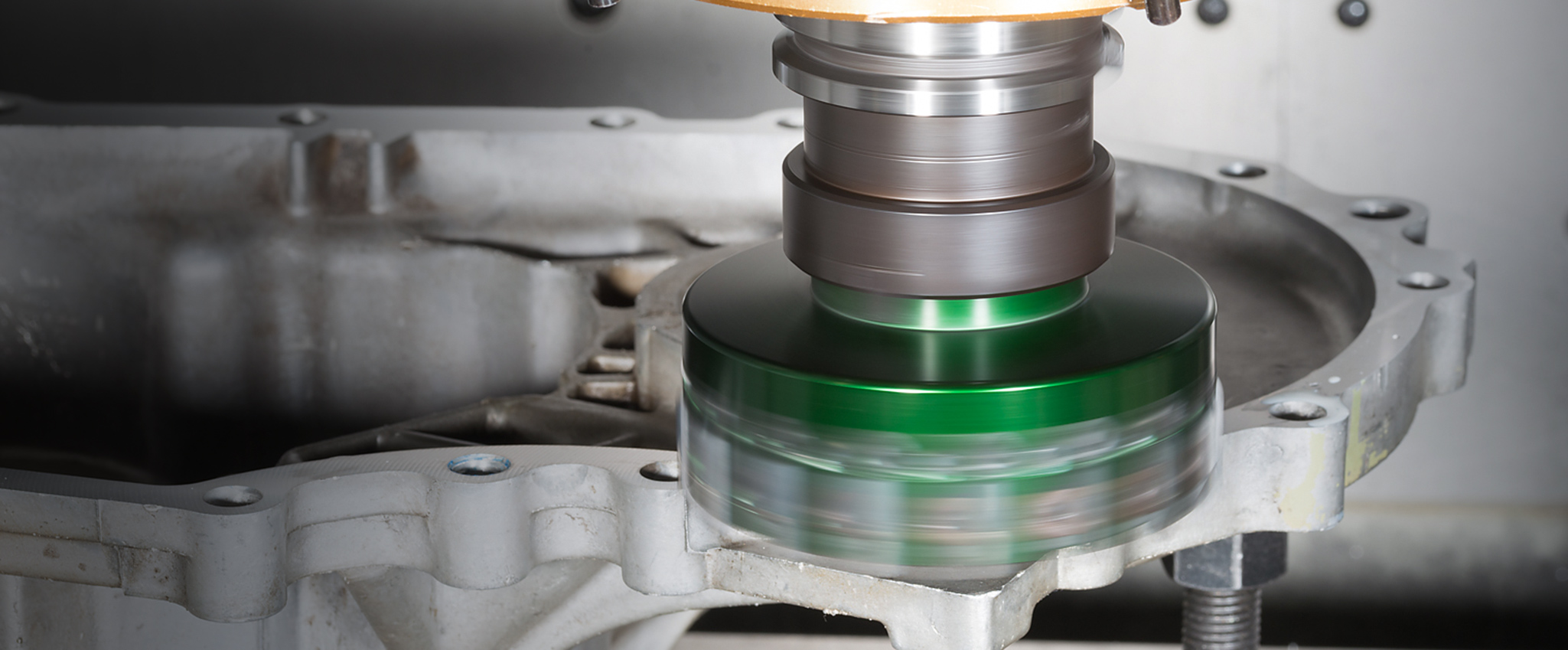

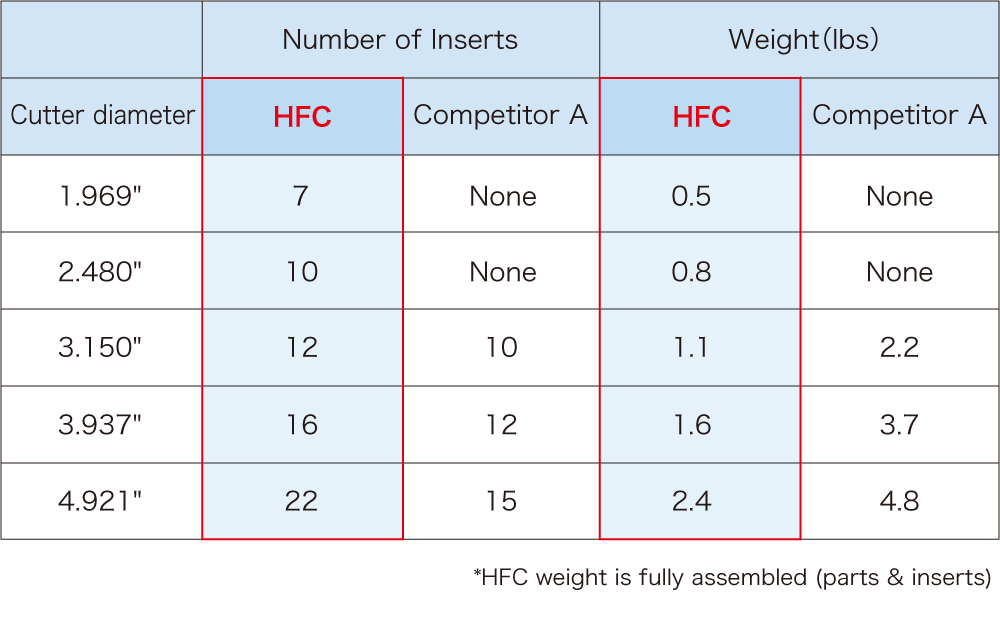

Cutter weight and insert comparison

HFC cutter weight is half that of others on the market

A 4.921" cutter + BT30 arbor* weighs 4.4 lbs or less.

At that weight, the 4.921" cutter can even be used on a compact machine!

* Using a BT30-FMNA25.4-40 (1.54 lbs)

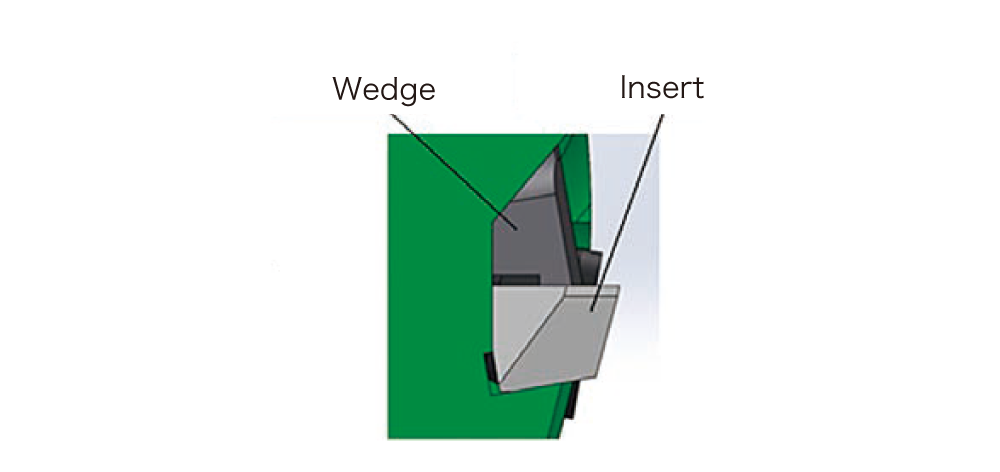

Safety clamp mechanism

Unique pocket design uses a wedge shape and centrifugal forces to help prevent the insert from sliding out.

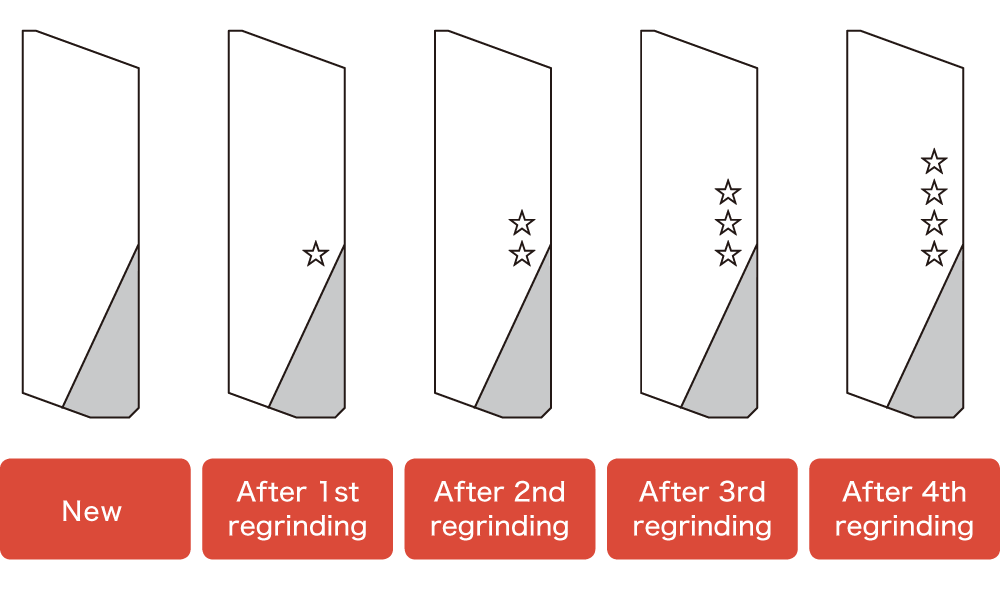

Insert can be reground up to 4 times

- Each regrind will reduce the width and height of the insert by 0.1mm(.004") from its previous dimension.

- A star is added to indicate the number of regrinds.

- Maximum number of regrinds is 4 times (the total dimensional change will be 0.4mm(.016") from the new product)

*The number of re-grinds per insert may vary depending upon cutting edge damage evaluation.

HFC cutter adjustment and handling procedure

Process

1. Loosen the axial adjustment screw

2. Install inserts (lightly hand tighten)

3. Clean the inserts

4. Adjust height of inserts (initial setup)

5. Tighten wedge set screw (firmly tighten)

6. Final insert height adjustment

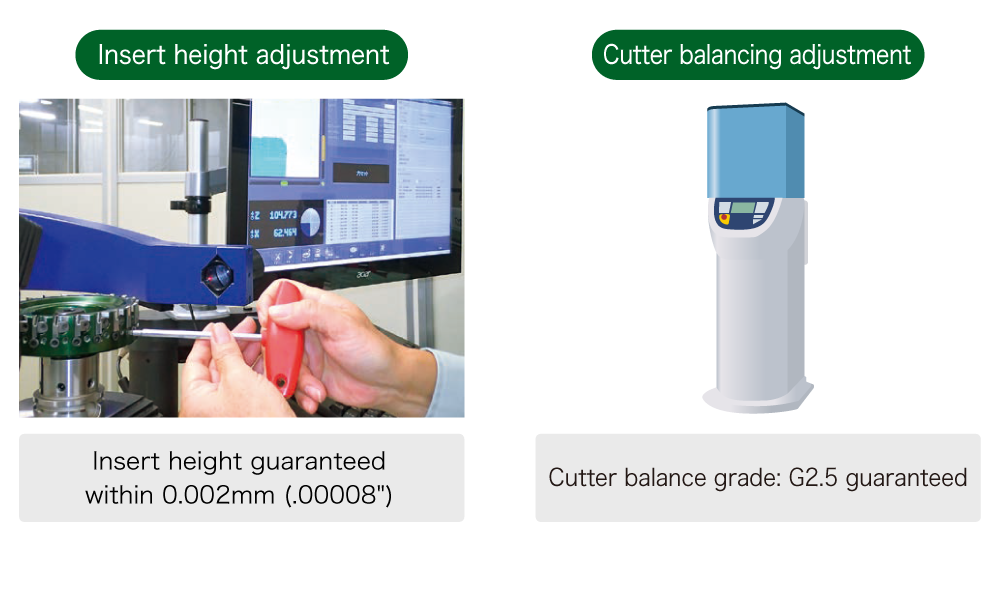

NTK cutter setup and balance service

- Preset and balancing service for new and reground inserts.

- We provide customers with safe and reliable machining.

Case study

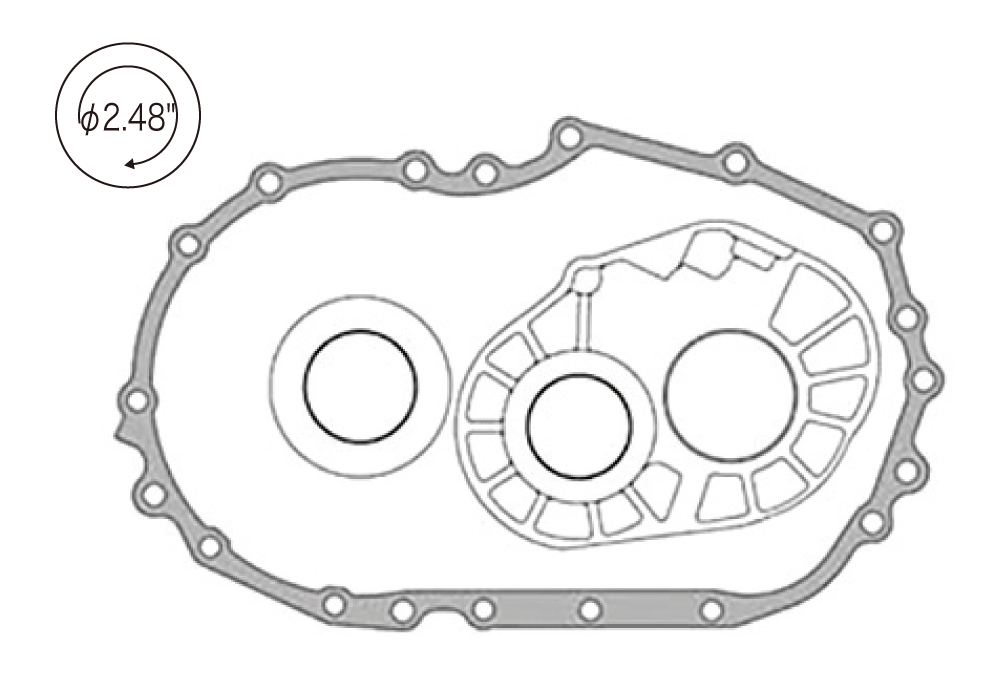

| Transmission case (φ2.48", 10 edges, WET) | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| HFC | 400 IPM |

| Competitor's PCD cutter | 310 IPM |

HFC cutter achieved 1.3 times higher productivity than the competitor's PCD cutter.

Tool lineup

Please check product catalog for tooling lineup

Other recommended products

-

PD1/PD2Non-ferrous material machining | PCD grades for Swiss CNC lathes

High speed, high efficiency machining

-

Ceramic and CBN for steel mill applicationsTools for mill roll turning | Ceramic and CBN inserts

High speed performance, longer tool life, and better part surface finish compared to carbide tools

Useful information

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕 Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕 Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics

Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics How to Make Ceramic Cutting Tools from Scratch

How to Make Ceramic Cutting Tools from Scratch